The "application scenarios" of carrier tapes: These industries cannot do without them

Carrier tapes, seemingly just plain plastic or paper strips, have become the "invisible must-have" for numerous industries due to their core capabilities of "precise carrying and safe protection". From our pocket phones to the precision instruments in hospitals, and even the speeding cars, carrier tapes are present behind each of them. The characteristics of components in different industries vary greatly, and corresponding carrier tapes have their own exclusive "skills". Today, let‘s take a look at the several major fields where carrier tapes are most frequently seen.

Consumer electronics industry: The "largest battlefield" for carrier tapes

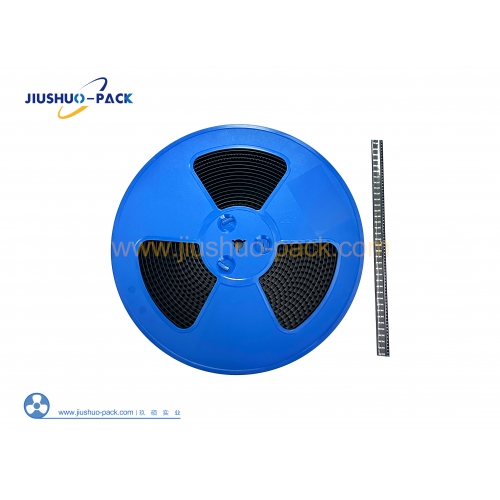

Consumer electronics is the industry where carrier tapes are most widely used. The production of products such as mobile phones, computers, smartwatches, and Bluetooth headphones all rely on the "protection" provided by carrier tapes. The components in this industry are characterized by "small, dense, and precise", and the corresponding carrier tapes also have core advantages of narrow width and high precision.

For example, the 0402 and 0603 specifications of resistors and capacitors on the main board of a mobile phone will use narrow carrier tapes with a width of 1.2mm and 2.0mm. The pits on the surface of the carrier tape precisely match the size of the components, and after the cover tape seals them, it can prevent the components from shifting or being worn during transportation and assembly. The small IC chips and camera module parts in mobile phones will use carrier tapes with a width of 8.0mm-12mm. Some carrier tapes will also be treated with anti-static treatment to avoid electrostatic breakdown of sensitive electronic components. The consumer electronics industry updates rapidly, and it has extremely high requirements for the delivery speed and size compatibility of carrier tapes. More than 70% of the regular carrier tapes in the market have flowed to this field.

Automotive electronics industry: "Hardcore" carrier tapes that are durable

The reliability requirements for components in automotive electronics are much higher than those in consumer electronics - components must work stably in high and low temperatures, vibrations, and humid environments. Corresponding carrier tapes also need to be "durable enough". The carrier tapes in this industry are mostly wide in size and thick in material, focusing on solving the problems of "large component fixation" and "extreme environment protection".

Power devices in the engine control module of an automobile, safety airbags‘ sensors, which are large in size and have complex pins, often use ultra-wide carrier tapes with a width of 24mm and 32mm. The sides of the carrier tape are designed with reinforcing ribs to enhance toughness, and the internal pits have anti-slip patterns to prevent the components from shaking. What‘s more special is the battery management components of new energy vehicles. Carrier tapes not only need to be able to withstand temperature changes from -40℃ to 120℃ but also need to have insulation properties. Most of them use modified plastic materials. In automotive electronics production, "zero damage" and "zero damage to components" are hard requirements. Once the carrier tape has a problem, it may directly affect the driving safety of the vehicle.

Semiconductor and integrated circuit industry: "Exclusive" carrier tapes with high precision

The semiconductor and integrated circuit industry is the application field where carrier tapes reach the "precision ceiling". The components in this industry, such as wafer fragments, precision probes, and micro transistors, often have dimensions measured in micrometers. The error control requirements for carrier tapes in this industry reach the level of 0.01mm.

For carrier tapes in the semiconductor industry, either ultra-narrow specifications of 0.4mm and 0.6mm are used, which are just suitable for the extremely small micro components; or custom carrier tapes with special positioning holes are used to ensure that the mounting equipment can accurately grasp the components. Some high-end semiconductor carrier tapes also use metal materials or ceramic coatings, which can avoid electrostatic interference and prevent the components from being contaminated by impurities on the carrier tape surface. In the chip packaging and testing process, carrier tapes are indispensable. They can orderly transport one by one chip to the testing equipment, significantly improving the testing efficiency.

Medical electronics and aerospace: Specialized "high-end carrier tapes"

Although the usage in medical electronics and aerospace industries is not as much as the first three, they have the highest customization requirements and can be regarded as the "special forces" of the carrier tape industry. Implantable components in medical electronics (such as parts of cardiac pacemakers) and sensing elements in diagnostic instruments not only require a sterile and non-volatile environment, but also must be biocompatible. Most of these carriers are made of medical-grade plastics, and some even need to undergo ethylene oxide sterilization treatment.

The carriers in the aerospace and aviation field need to withstand the extreme environments of space. For example, the carrier for electronic components on satellites must be resistant to radiation, vacuum, and be able to withstand the huge impact force during launch. The materials often choose high-strength polyimide. These special carriers have small production volumes and complex processes, and their prices are often several to dozens of times higher than regular carriers. However, they are crucial for ensuring the stable operation of high-end equipment.

In addition, LED displays, industrial control, smart home, and other industries also have carriers. The logic of the industry application of carriers is simple: as long as there is a need for the production and transportation of precision components, corresponding carriers need to be "tailor-made". It is like the "exclusive express box" for components, although it is unremarkable, it plays an irreplaceable role in the industrial chain of various industries.

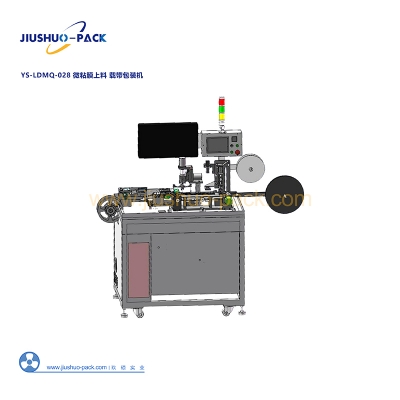

Jiushuo has been dedicated to precision carriers for 17 years. It provides a series of carrier materials for major manufacturers such as ZTE, Huawei, and Apple. It also cooperates with military enterprises and the pesticide industry for carrier materials. Jiushuo is involved in multiple fields of carriers. Various carriers are flourishing everywhere!