About Carrier Tape Dimensions: Practical Analysis of Common and Special Sizes

In the production and transportation processes of electronic components, the carrier tape is like the "exclusive vehicle" for the components. It safely transports the precise parts such as resistors, capacitors, and chips, and the size of the carrier tape directly determines whether the "vehicle" fits well. Many people have only seen the commonly used carrier tapes in assembly lines, but they don‘t know that the carrier tape sizes vary greatly in different scenarios. Today, let‘s talk about the nuances of carrier tape sizes, from common specifications to special models, one by one.

Common in Daily Use: Common Carrier Tape Sizes in the Electronics Industry

The reason why common carrier tape sizes are "common" is that they are adapted to the most widely used component specifications in current electronic devices. These sizes have been verified through long-term market testing, and they have the best cost-effectiveness and universality. In terms of width, the 1.2mm, 2.0mm, 4.0mm, and 8.0mm specifications can be regarded as the "main force".

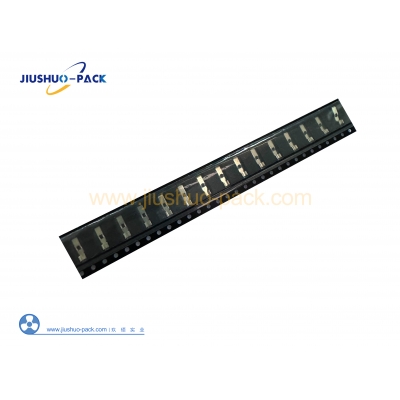

The carrier tapes with a width of 1.2mm and 2.0mm are mainly used to load small surface-mount resistors and capacitors like 0402 and 0603. The small components that are densely arranged in our daily-used mobile phones and smart watches are mostly carried by them. The depth of the cavities (the slots for holding components) of these carrier tapes is usually between 0.8mm and 1.5mm, which can just fit the small components without shaking. The carrier tapes with a width of 4.0mm are more widely used. From 0805 specification resistors to small diodes and transistors, they can all be loaded. The depth of the cavities also expands to around 2.0mm, and many control boards of household appliances cannot do without it.

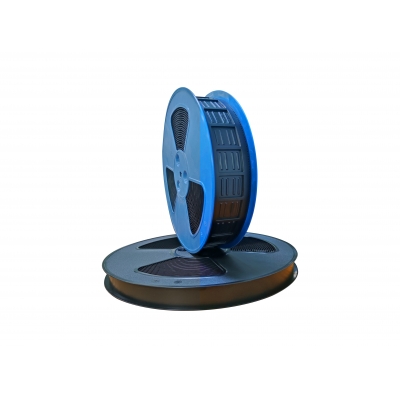

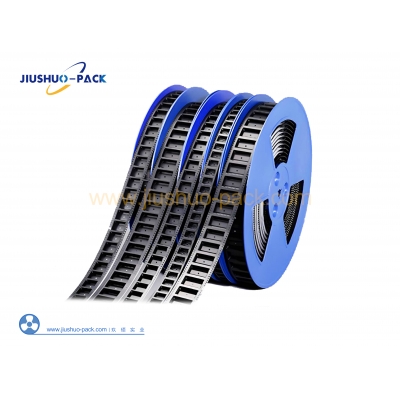

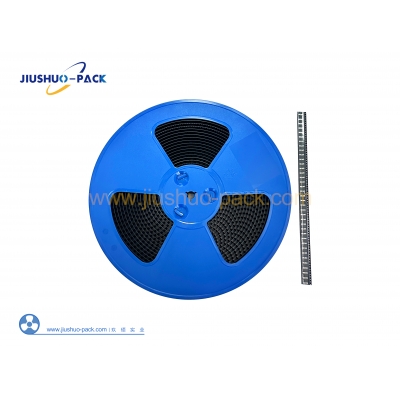

Carrier tapes with a width of 8.0mm and above are more suitable for "medium-sized components", such as surface-mount inductors and small IC chips. Their cavities are not only deeper (3mm-5mm), but some are also designed with special shapes to match the pins of the components. Besides width, the length of the carrier tape also has default specifications, mostly 50 meters per roll, which is just suitable for the feeding mechanism of the automatic dispensing machine, and the efficiency is the highest when changing materials. Additionally, the size of the accompanying reels also matters. The common 13-inch reels are paired with narrow carrier tapes, while the 7-inch reels are paired with wide carrier tapes. This way, the reels are stable and do not occupy much space.

Special but Crucial: Uncommon Carrier Tape Sizes for Specific Scenarios

Uncommon carrier tape sizes are not "rare and useless", but they are designed to meet the "customized travel" needs of special components. These sizes often correspond to high-end manufacturing or specific industries. The most typical ones are ultra-narrow and ultra-wide carrier tapes. Their sizes exceed the conventional range, but they are indispensable in specific fields.

Ultra-narrow carrier tapes often have a width smaller than 1.0mm, such as 0.4mm and 0.6mm specifications. They are mainly used to hold precision probes in the semiconductor industry and miniature sensors, which are smaller than sesame seeds. Ordinary carrier tapes cannot fix these components. The production precision of these carrier tapes is extremely high, with the cavity error controlled within 0.01mm. Otherwise, there will be problems with component detachment. They are widely used in micro-circuits of medical equipment.

Ultra-wide carrier tapes go to the other extreme. Carrier tapes with widths of 24mm, 32mm, and even 56mm are not rare. They are the "exclusive buses" for large components. For example, the lamp beads of LED display modules and power components in automotive electronics. These components are large and have many pins, which cannot be loaded by ordinary carrier tapes. Ultra-wide carrier tapes not only have larger cavities but also design reinforcing ribs on both sides to prevent deformation during transportation. There is also a special "thick-wall carrier tape", although the width is conventional, the depth of the cavity can reach over 10mm, specifically used to hold power chips with heat sinks. This carrier tape even uses metal materials to enhance load-bearing capacity.

In addition to length and width, there are "special-shaped carrier tapes" as well. For example, the "step-shaped cavities" carrier tapes designed for connectors, with one side deeper and the other side shallower, precisely matching the concave-convex structure of the connectors. There is also an "electrostatic-free tape" specially designed for optical components. Although its size is similar to that of ordinary tapes, its surface has been specially treated. Even if the size is very small, it will not cause electrostatic damage to the components.

In fact, there is no "good" or "bad" in the size of the tape; it only depends on whether it is suitable or not. Common sizes are the result of market selection, while uncommon sizes reflect the refinement upgrade of manufacturing. From small resistors in mobile phones to large chips in cars, the change in tape size is essentially adjusting in line with the pace of technological development. These seemingly ordinary plastic tapes are the important guarantee for the precise production of electronic products.

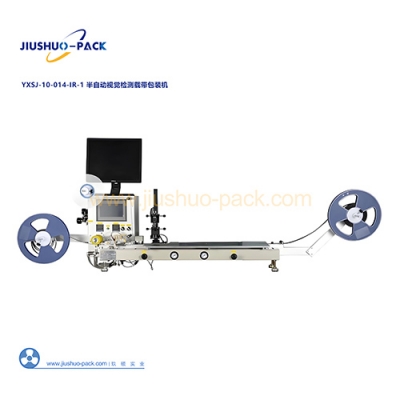

Jiushuo‘s Carrier tape sizes all have non-standard tape sizes that can also be customized. They can help you find the most suitable matching tape. They can also provide tape mold making, roll wrapping, tape threading, tape packaging, and other supporting services!