Understanding Hardware Carrier Tape in One Read

In the assembly workshop of electronic devices, you may have witnessed such a scene: Automated machines precisely "grab" small hardware parts from rolls of tape-like packaging and quickly complete the installation. These "tapes" carrying the hardware parts are precisely what we call hardware carrier tapes. Although seemingly ordinary, they are the "invisible heroes" of efficient automated production in the electronics manufacturing industry. Without them, the assembly efficiency of countless precision devices would be greatly reduced.

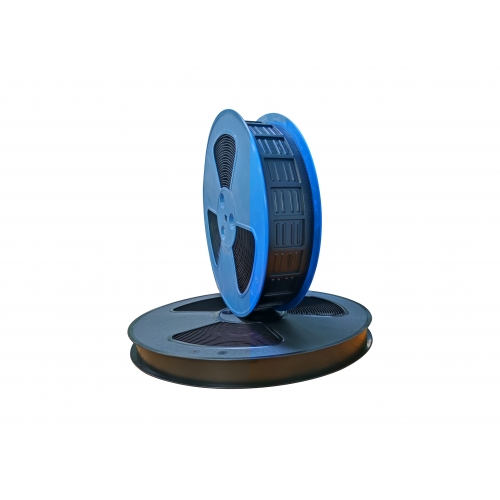

What exactly is a hardware carrier tape? In simple terms, it is a packaging carrier specifically designed to hold and protect small hardware parts, and to enable precise transportation and retrieval of the parts through automated equipment. It is usually made of plastic or paper materials, with neatly arranged grooves on the tape according to the shape and size of the hardware parts. The parts are embedded in these grooves and a layer of film is covered for fixation. The edges of the carrier tape also have evenly distributed positioning holes, through which the automated equipment can precisely control the movement rhythm of the carrier tape, ensuring that each part arrives at the designated position on time. Its core function is to solve the problems of easy loss, difficult positioning, and easy wear of small hardware parts, providing support for large-scale production.

Depending on the type of hardware parts it carries, hardware carrier tapes have derived several commonly used subcategories. Among them, terminal, screw, nut, and spring carrier tapes are the most common. They play an irreplaceable role in their respective fields.

Terminal carrier tape is the "exclusive manager" in the field of electronic connections. Terminals, as key parts for circuit connections, are mostly thin and have precise contacts. Once they deform or get stained, they will affect the conductivity. The grooves of the terminal carrier tape are customized according to the number and arrangement of the terminals‘ pins to ensure that the terminals maintain a fixed posture during transportation and retrieval, and the pins will not bend. At the same time, the sealing property of the carrier tape can also prevent dust and moisture, keeping the terminals in a "ready" state, especially suitable for the assembly of precision electronic devices such as mobile phones and computers.

Screw carrier tape is a powerful tool for solving "small screws big problems". Although screws are small, they are the core components for equipment fixation. Especially for micro screws, the diameter is often less than 2 millimeters, and manual retrieval is not only inefficient but also prone to falling off. Screw carrier tape is designed with grooves according to the head shape (cross, straight, internal hexagon, etc.) and length of the screws. Some carrier tapes also add anti-slip structures to prevent the screws from rotating during movement. After the automated equipment positions the carrier tape, it can directly "grab" the screws for installation, significantly improving the assembly speed of appliances and automotive electronics.

Nut carrier tape focuses on the "precise matching" function. The screw and nut are used together, and the integrity of the screw‘s thread directly affects the connection‘s firmness. The inner wall of the grooves of the nut carrier tape is specially treated to neither scratch the thread nor firmly fix the nut position. In assembly lines, nut carrier tapes can precisely cooperate with the screw feeding mechanism to achieve synchronous installation of "screw-nut", avoiding the mismatch problem during manual matching, and are particularly suitable for batch assembly of mechanical components.

Spring carrier tape focuses on the "elastic protection" requirement. Springs rely on their own elasticity to achieve functions such as reset and buffering. Once they are compressed and deformed, they will lose their effectiveness. The depth and width of the grooves of the spring carrier tape are carefully designed according to the outer diameter and compression amount of the spring to ensure that the spring is placed in a natural state and will not be compressed. At the same time, the breathable design of the carrier tape can prevent the spring from getting damp and rusting, allowing these "small springs" to function stably in devices such as door locks and medical equipment.

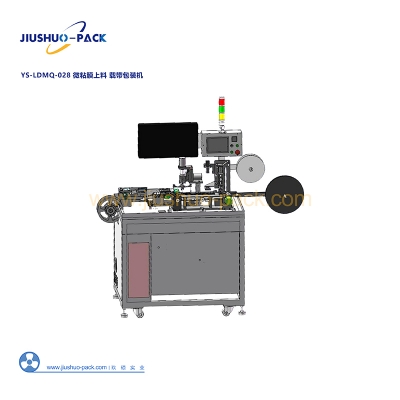

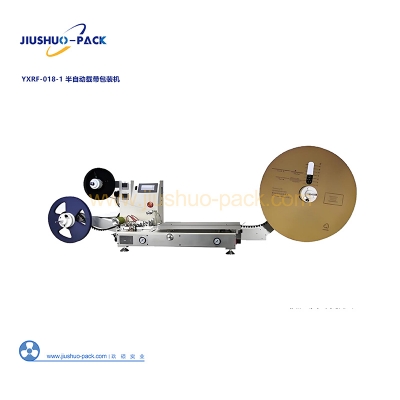

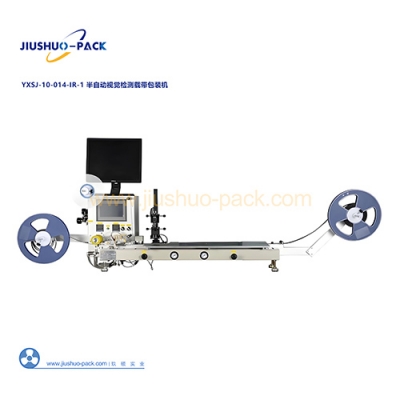

Although these subcategories of carrier tapes have different shapes, they all follow the principle of "tailor-made". With the development of intelligent manufacturing, hardware carrier tapes are constantly upgrading, such as using anti-static materials to meet the requirements of electronic components, and adding transparent windows for visual inspection. This small carrier is, in its own way, supporting the efficient operation of modern manufacturing, and has become an indispensable production assistant.

Jiushuo‘s above-mentioned hardware carrier is very experienced and offers a wider range of styles. Welcome to place an order and consult!