Carrier Tape: Compliance Standards and Technical Requirements

In the "flowing life line" of electronic components, the carrier tape is an indispensable core packaging medium. It not only needs to securely hold precise components such as resistors and chips, but also needs to be compatible with the high-speed operation of automated assembly equipment.

Whether the carrier tape can perform this task well depends crucially on whether it complies with the globally applicable compliance norms - among which the ANSI/EIA 481-F:2021 standard is the "golden rule" in the industry.

The EU‘s RoHS directive is the "hard threshold" for environmental protection, and there are also a series of technical standards such as electrostatic protection and dimensional accuracy, which together form the compliance system of the carrier tape.

The compliance of the carrier tape must first "match the specification", because different types of carrier tapes correspond to different detailed regulations.

The ANSI/EIA 481-F:2021 standard clearly divides carrier tapes into two categories: punched carrier tapes and embossed carrier tapes:

Punched carrier tapes mostly use paper-based or composite paper materials, with widths mainly ranging from 8mm to 12mm. They are mainly suitable for small discrete components such as resistors and capacitors. These carrier tapes have strict regulations on hole diameter tolerance and edge flatness in the EIA standard.

Embossed carrier tapes are made from plastics such as PS and ABS, and are molded through molds. Their widths range from 4mm to 200mm, and are specifically used to load precision components such as integrated circuits and BGA chips. The cavity shape and wall thickness uniformity of these carrier tapes must also meet the standard requirements.

Especially for 4mm micro-sized embossed carrier tapes, the EIA standard additionally emphasizes "directional accuracy" - the component pins must be completely aligned with the positioning marks on the carrier tape, with an error not exceeding 0.1mm, which is the basis for ensuring that the automated assembly does not go wrong.

Dimensional accuracy is the core assessment item of the EIA standard and can be regarded as the "life line" of the carrier tape.

The standard has differentiated dimensional requirements for different width carrier tapes: For example, for 8mm punched carrier tapes, the center spacing of the cavity is fixed at 2.0mm, and the maximum allowable error is only ±0.05mm, which is equivalent to 1/7 of the diameter of a hair; for 24mm embossed carrier tapes, the depth tolerance of the cavity needs to be controlled within ±0.1mm, otherwise there will be problems such as "not being able to fit" or "shaking" the components.

Why is it so strict? Because the picking mechanism of the automated assembly equipment is set strictly according to the size parameters of the EIA standard. If the size of the carrier tape exceeds the limit, it will lead to "empty picking", "wrong picking", and even damage to the assembly needle. In addition, the EIA standard also requires the "pitch consistency" of the carrier tape, with a cumulative error of no more than 0.5mm for every 100 cavities, to ensure the stability of continuous operation of the equipment.

Sealing performance and electrostatic protection are the "double guarantees" for the compliance of the carrier tape, both of which are clearly defined in the EIA standard.

Sealing performance is mainly measured by the peel strength of the covering tape: The peel force of 4mm carrier tapes needs to be between 0.1N and 0.7N (approximately the force required to pick up a paperclip), while 56mm carrier tapes are allowed to reach 1.2N. Regardless of the specification, it must meet the requirement of "uniform peel force" - the EIA standard stipulates that the peel force fluctuation of the same roll of carrier tape must not exceed 30%, to avoid situations such as "partially not peeling and partially breaking". During the test, the EIA standard also clearly stipulates that the peel speed is 300mm/minute, which is completely matched with the working rhythm of mainstream assembly equipment.

Electrostatic protection: The EIA standard directly references the ANSI/ESD S541 electrostatic protection guideline, requiring the surface resistance of the carrier tape to be controlled between 10^6Ω and 10^12Ω - neither conductive (to avoid component short circuits) nor able to effectively dissipate static electricity (to prevent static breakdown of components). Therefore, compliant tapes usually add anti-static agents or adopt conductive coating processes. Meanwhile, the EIA standard also requires that the tape packaging must be equipped with anti-static bags, and the storage environment humidity should be controlled at 40%-60%. This way, the risk of static electricity can be avoided throughout the entire chain. Additionally, the physical stability of the tape cannot be ignored: the EIA standard stipulates that the warpage within a 250mm length should not exceed 1mm, and the lateral movement of components within the cavity should be ≤ 0.5mm. These requirements are all to ensure that the tape can smoothly pass through the conveying track of the assembly equipment.

Apart from the "general specification" of the EIA standard, the tapes exported to the EU must also comply with the environmental protection requirements of the RoHS 2.0 Directive (2011/65/EU). This is the "ticket" for entering the European market. The RoHS directive clearly limits the content of six harmful substances such as lead, cadmium, and mercury in the tape materials, with the maximum allowable concentration of cadmium being only 100 ppm and lead being 1000 ppm. This means that tape manufacturers must strictly screen the raw materials - for example, plastic carriers cannot use lead stabilizers, printing inks need to adopt mercury-free formulations, and they must provide RoHS testing reports from authoritative institutions such as SGS to ensure that each batch of products meets environmental protection requirements. Moreover, the RoHS directive also requires that the outer packaging of the tapes be marked with the "CE" logo and clearly indicate the material composition information for easy traceability.

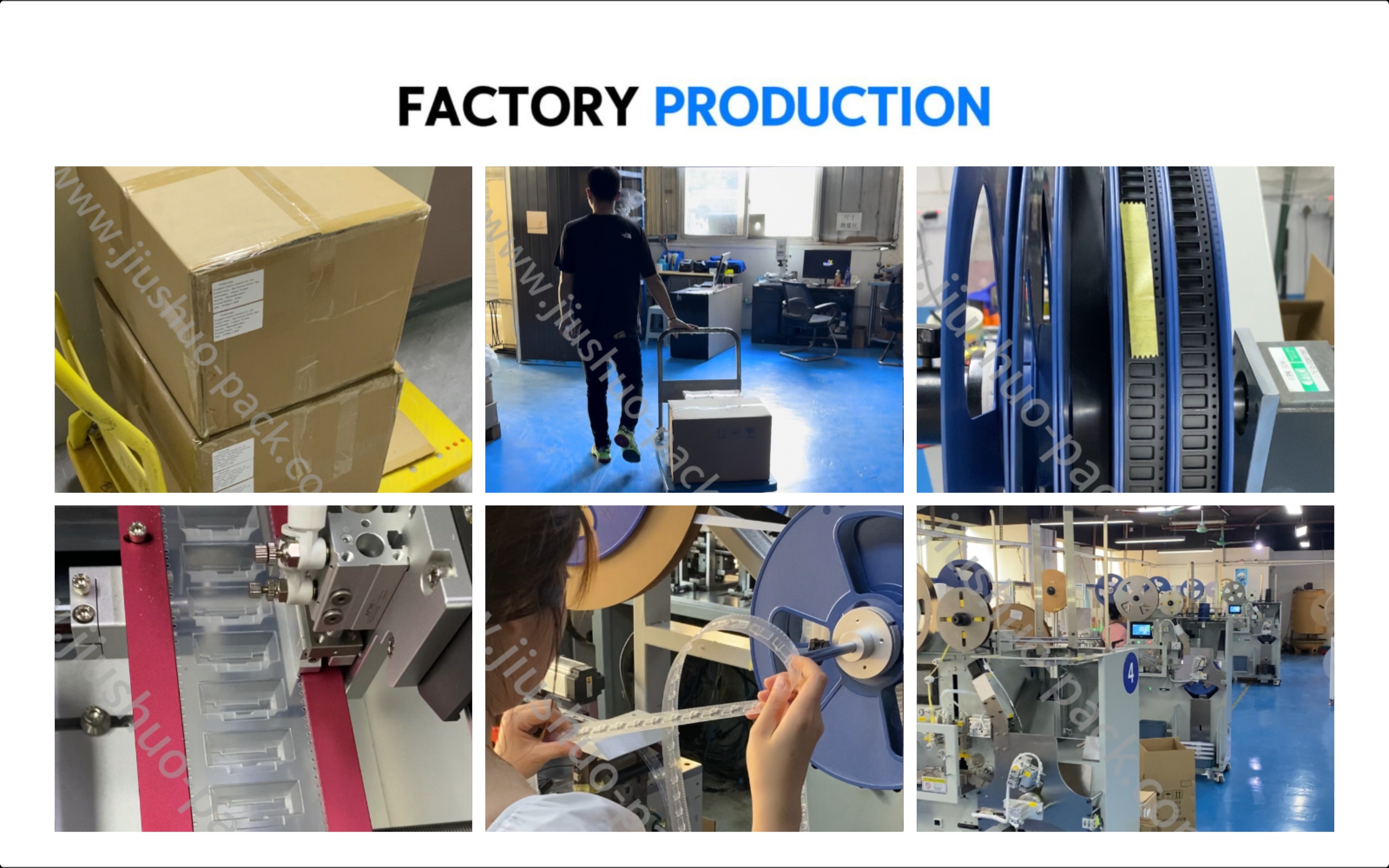

In actual production, tape compliance is the result of "full-process control" rather than an endpoint.

When enterprises purchase tapes, they must clearly indicate in the contract "compliant with ANSI/EIA 481-F:2021 standard and RoHS 2.0 Directive requirements", and require the suppliers to provide third-party test reports; before storage, key indicators should be sampled tested - using calipers to measure the dimensional accuracy, using peel force testers to test the sealing performance, and using static testers to verify the anti-static effect; during production, attention should also be paid to the compatibility between the tape and the cover tape, because even if both are compliant individually, improper matching may lead to sealing failure problems.

For tapes exported to Japan and South Korea, additional local standards such as JIS C 0806 and KSC 8100 must also be met. These standards differ slightly in terms of size tolerance and environmental protection requirements from the EIA standard, and it is necessary to make appropriate adaptations in advance.

In summary, tape compliance is essentially a process of "coordinated implementation of multiple standards": the ANSI/EIA 481-F:2021 standard builds a technical framework for size and performance, the RoHS directive builds a bottom line for environmental protection, and the ANSI/ESD S541 guideline fills the gap in electrostatic protection.

These standards may seem cumbersome, but each one corresponds to a production pain point - size specifications avoid assembly failures, environmental requirements open up the international market, and electrostatic protection reduces component losses. For electronic enterprises, mastering these compliance standards not only helps avoid quality risks but also enhances the stability of the supply chain, making the tape truly a "safety guardian" for precision components.

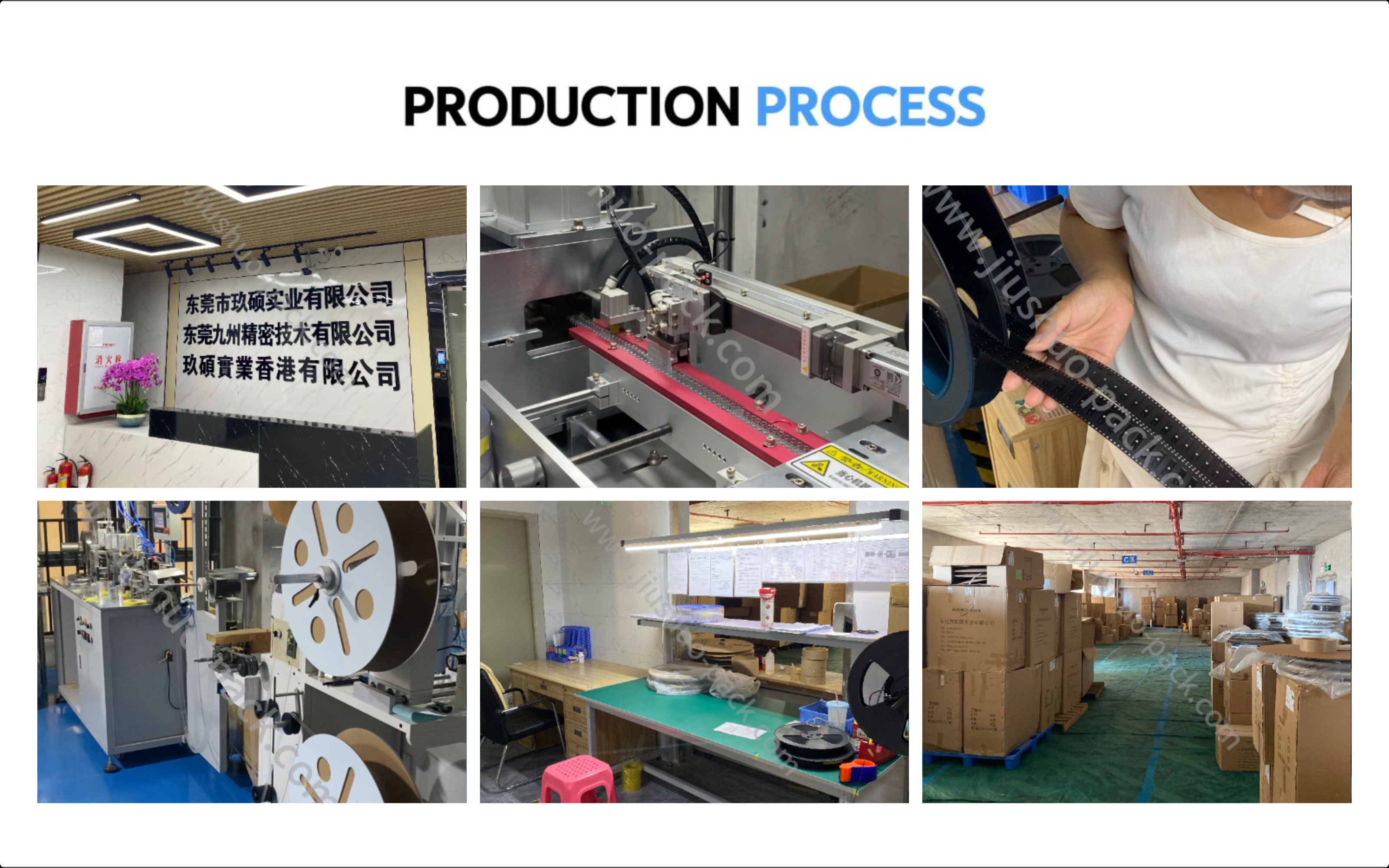

Jiushuo‘s Carrier tapes currently all comply with the EIA 481 international standard, RoHS standard, and electrostatic protection standard! And they have relevant qualification certificates and issue reports annually.