Understanding Tape Specifications:

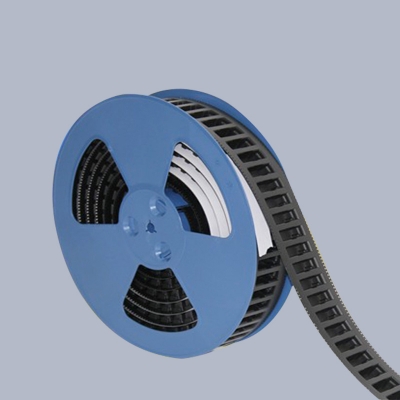

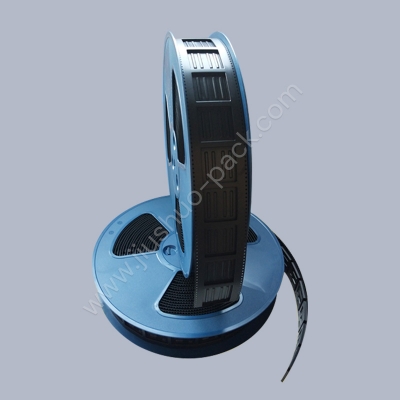

The tape seems simple, but in fact it is a sophisticated standardized system. Its specifications are the "common language" that ensures that a wide variety of electronic components can be accurately identified and installed on the same automated production line. Understanding the specifications of the tape mainly involves the following four core dimensions:

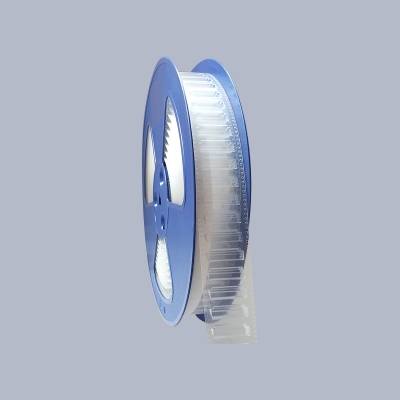

1.Bandwidth: Determines the width of the "runway"

This is the most intuitive specification, referring to the total width of the carrier tape, measured in millimeters. It is like different widths of movie film, corresponding to different projectors.

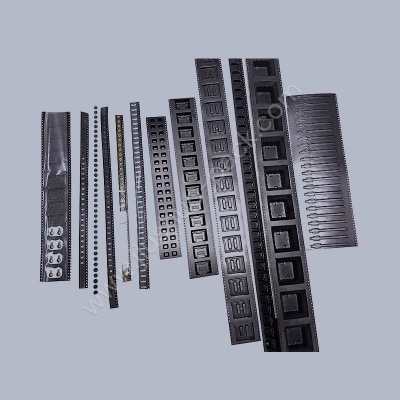

Common specifications: 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, etc.

How to choose: The larger the size of the component, the wider the carrier tape required. The feeder of the SMT assembly machine must also match the corresponding bandwidth.

2. Pocket spacing: "Interval" of component seats

Refers to the distance between the centers of two adjacent pockets on the carrier tape. The most common specifications are 2mm and 4mm.

Function: This spacing precisely corresponds to the "step" distance that the soldering machine moves the carrier tape each time, ensuring that every component can be accurately delivered to the fixed grasping position.

3. Pocket Specifications: "Custom Seat" for Components

This is the most crucial part of the specifications, which is determined directly by the shape and size of the components.

Size: The length, width and depth of the pocket must be precisely matched to the components. If it is too small, the components cannot fit in; if it is too large, the components may shake or flip during transportation.

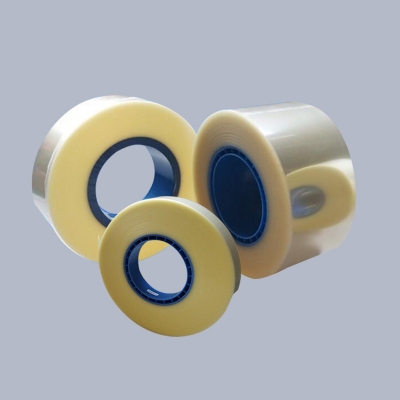

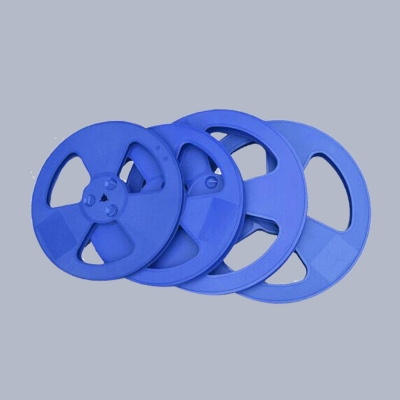

Type: It is divided into tape carriers and tape reels.

Carrier: Refers to a baseband that has its own pockets.

Tape: Refers to the process of "stitching" components onto a flat strip, and is sometimes collectively called a carrier tape.

4. Guide holes: "Positioning gauges" for automated production

The positioning holes located on both sides of the carrier belt have extremely high precision in terms of their diameters and spacing.

Function: The gears of the assembly machine engage with these guide holes to achieve precise transportation at the millimeter level. This is the fundamental guarantee for achieving high-speed automation.

In summary, a complete tape specification is defined by a set of parameters including [bandwidth], [spacing], [pockets], and [through-holes]. It ensures that from the component manufacturer to the SMT workshop, all equipment and processes can "speak the same language", thereby enabling efficient and error-free automated production.

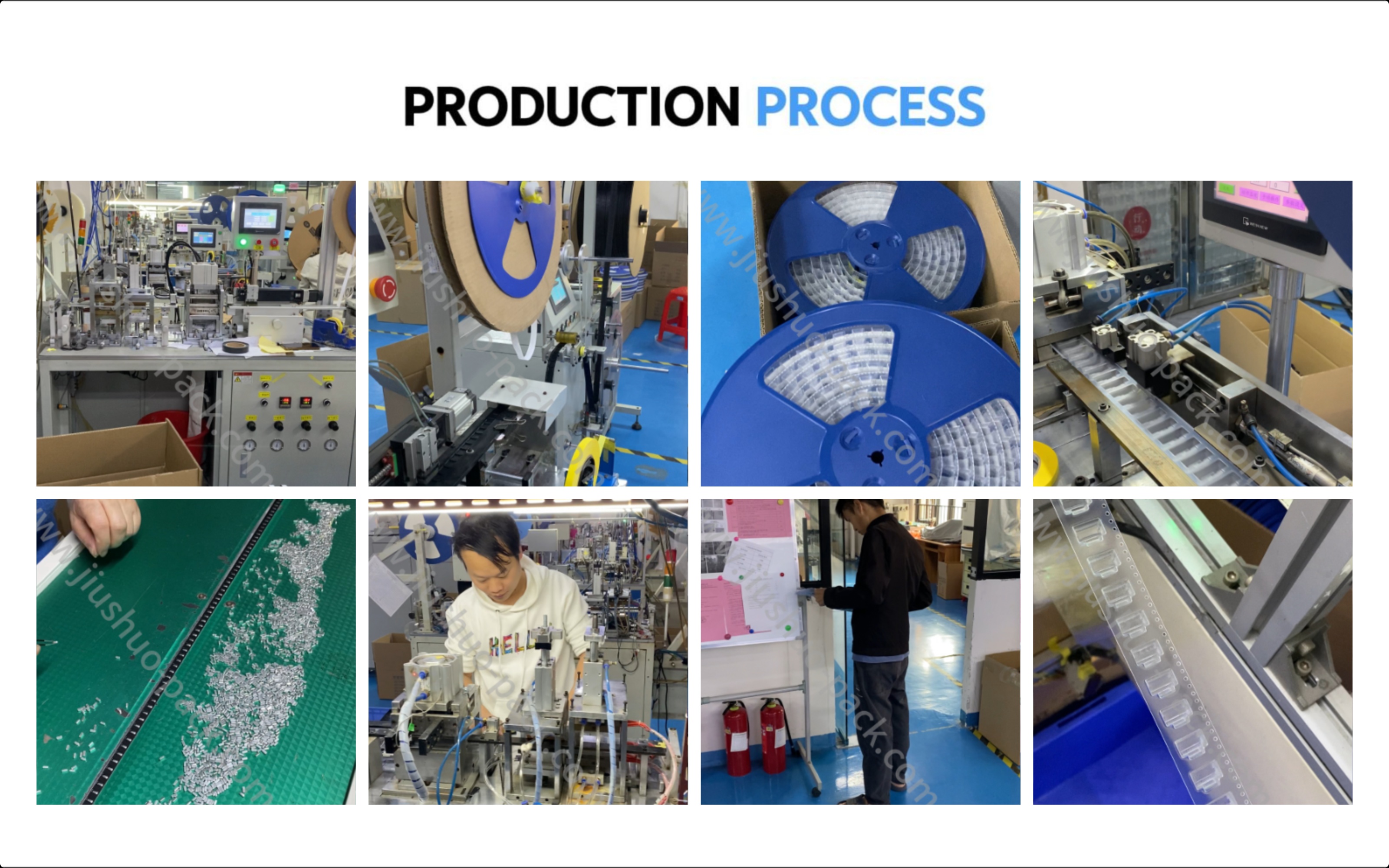

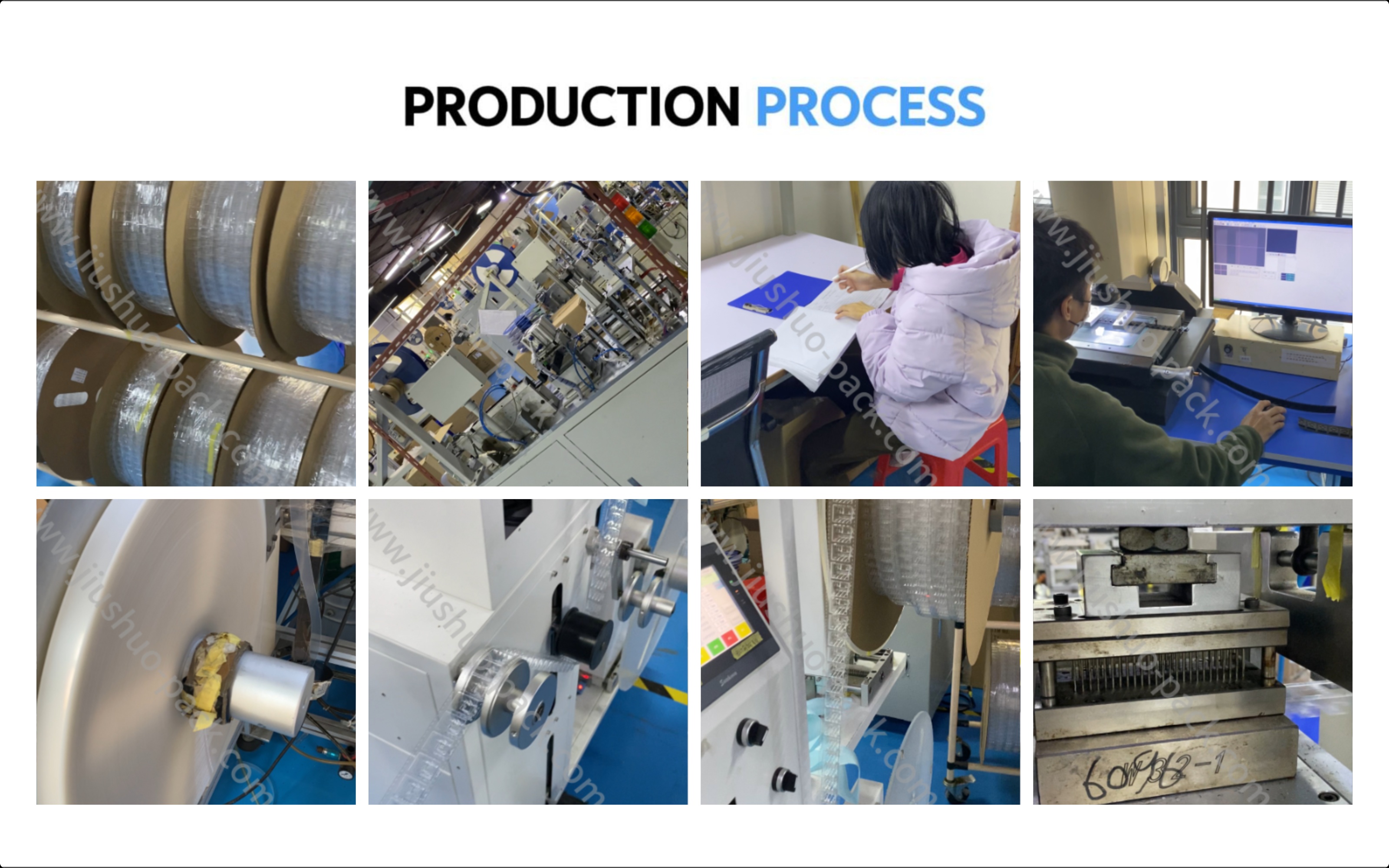

Jiushuo has a professional secondary product inspection room, its own mold workshop, and experienced mold technicians. They can ensure that the specifications and sizes of the tapes you need are precise. If you are not sure, you can provide us with the products that require customization of the tapes. We will help you develop and design them, and provide you with the best solution!