What is a carrier tape?

Professional Definition:

Tape carrier is a packaging material used for carrying, transporting, and protecting SMT electronic components (such as chips, modules, connectors, inductors, and capacitors). It is a key component in modern electronic manufacturing for achieving efficient and automated production.

In layman‘s terms: Have you ever wondered how those tiny electronic components in your mobile phones, computers, and 3C products, which are smaller than your fingernails, are transported neatly to the factory and precisely placed on the PCB without any damage?

The answer is "tape carrier", a packaging tool that serves as a "mobile house" for SMT micro-components.

The appearance of tape carrier is quite intuitive: it is a long, thin plastic strip with small grooves (referred to as "cavities" in the industry) dug at fixed intervals. All dimensions comply with the EIA-481 standard. Each groove is like a "single-person compartment" tailored for a component, precisely fitting a small part. After the components are placed in the grooves, a thin cover tape is attached to the surface of the tape carrier, sealing the products in the grooves tightly. This way, the components won‘t fall out, get scratched, or accumulate dust.

The core function of tape carrier is to serve as a "dedicated transportation and storage container" for micro-components. It can package components ranging from a few millimeters in size, such as connectors and modules, to precision hardware parts, and even chips smaller than sesame seeds.

During SMT assembly in factories, workers only need to load the tape carrier onto automated equipment. The machine can precisely lift the cover tape and pick out the components, eliminating the need for manual placement on the PCB, thus avoiding contamination and damage. Through tape carrier packaging, efficient and automated production is achieved.

The carrier tape is composed of the following:

Base tape: A long, strip-shaped carrier, usually made of plastic (such as PS, PET, ABS) or paper-based materials.

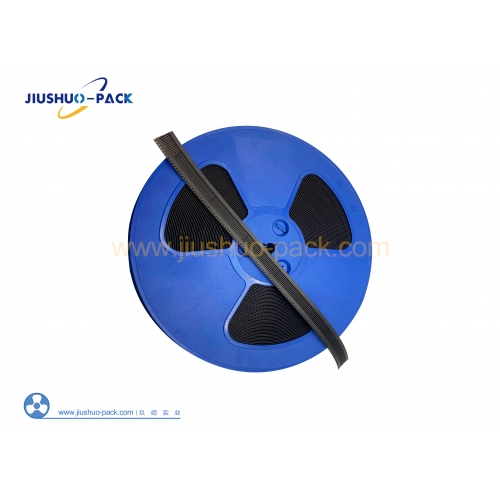

Figures 1 and 3 show the appearance of the magnetic tapes we produce.

.jpg)

Pocket: The orderly arranged holes on the base tape, used for precisely positioning individual electronic components.

Cover film: A transparent heat-sealing film covering the top of the tape, sealing the components within the pocket and preventing them from falling and getting contaminated.

Through holes: Precisely positioned holes at the edge of the tape, through which gears on the automated equipment will be inserted to precisely and step-by-step transport the tape forward.

Figure 6 clearly shows the pockets we carried, which are also the cavities, as well as the guide holes on the sides.

Usage: Primarily used to support SMD components (such as surface mount devices) that are precise and of high value.

The three attached pictures both show some of our Jiusuo‘s production tapes, as well as the details of the tapes, the components they carry, and the working conditions of the employees during production and quality inspection of the tapes.

Summary in one sentence:

A carrier tape is a standardized packaging tape that encapsulates scattered tiny electronic components through pockets and a covering film, and precisely locates and transports them through side-mounted guide holes. It is the cornerstone for achieving fully automated electronic manufacturing.

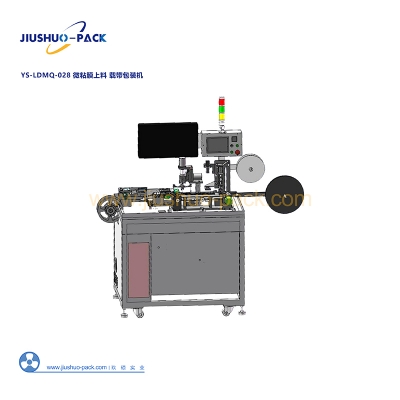

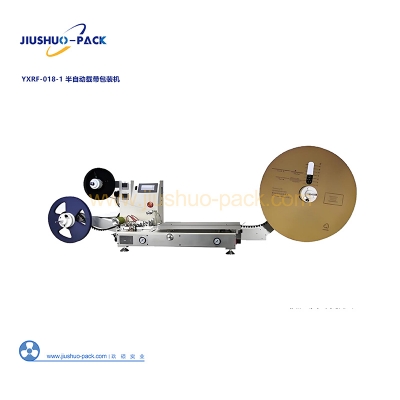

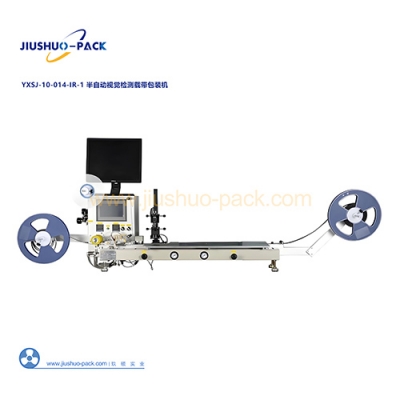

At present, the Jiushuo tape factory in the market produces high-quality tapes with excellent service and low unit prices, which all fully meet the customers‘ requirements. We provide customers with complete sets of products including tapes, spools, cover tapes, tape packaging machines, allowing customers to make one-stop purchases.