Product details:

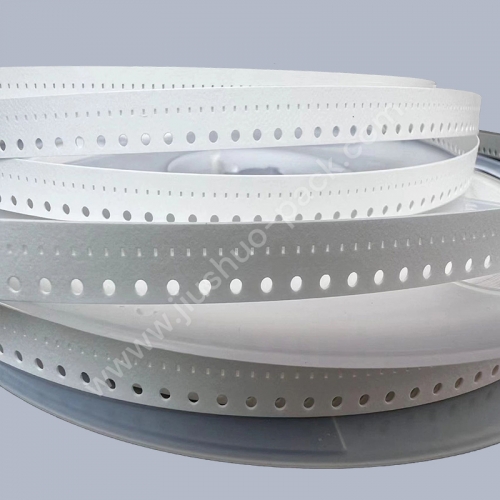

Product Name: Punched paper carrier tape

Product thickness: 0.31~0.95mm

Product specifications: 8mm, 12mm, 16mm

Material and process: Bleaching of raw wood pulp paper, operated by a long mesh machine.

Product characteristics: The paper has no shedding of hair or powder, good thickness uniformity, good flatness, no impurities on the surface, strong adhesive strength without layering, and perforated holesThe wall is smooth without burrs.

Scope of application: Widely used in electronic components such as IC resistors, inductors, capacitors, LED switches, etc.

Perforated paper carriers are formed through die punching to form penetrating or semi penetrating cavities. The thickness of electronic components that can be held by this type of carrier is limited by the thickness of the carrier itself, and can generally only be used for packaging smaller components. Paper carriers have advantages such as good rebound, convenient preparation, and low cost. However, the strength requirements for the carrier paper used for packaging and transportation of electronic components are very high; Good adhesion, during the punching and slitting process, paper carrier paper usually consists of three layers (or more) of structure, namely the surface layer, middle layer, and bottom layer. The carrier belt is evenly distributed with positioning holes and cavities, which are used to hold electronic components and are sealed inside the carrier belt through upper and lower sealing tapes. The structure is shown in Figure 1.

The lower sealing tape can prevent electronic components from leaking out from the bottom, while the upper sealing tape is often coated with hot melt adhesive, which serves as the upper part of the packaging pocket. Electronic components determine the shape and size of the cavity, usually consisting of through holes, stepped holes, and blind holes. The machining accuracy requirements for holes are high. It is necessary to strictly control the amount of powder falling from the hole cavity, while ensuring sufficient machining accuracy to avoid mechanical vibration damage to electronic components during use and transportation engineering

Good quality comes from good materials, and the perforated paper carrier is made of raw wood pulp paper, which is formed in one go without layering. Plant fibers and paper are smooth, moderate, and have good toughness, without damage when folded.