The cost of the carrier tape should not be judged solely by the quotation!

Jiushuo‘s "cost-saving logic" is more practical.

"When this carrier tape of tape is 2 cents cheaper per meter, choose it!" Many electronic enterprises often get led by the surface quotation when purchasing tapes, but after calculating the "total bill", they regret deeply: urgent replenishment incurs double shipping costs, tape breakage leads to production line shutdown, and the loss of chips is ten times more expensive than the saved money. The "cost" of the tape is never just the quotation; it is the comprehensive expenditure of procurement, production, and logistics throughout the chain.

jiushuo, with its full-chain layout, transforms the advantages of intelligent equipment and multiple factories into real money-saving services, helping customers calculate the "cost-saving account".

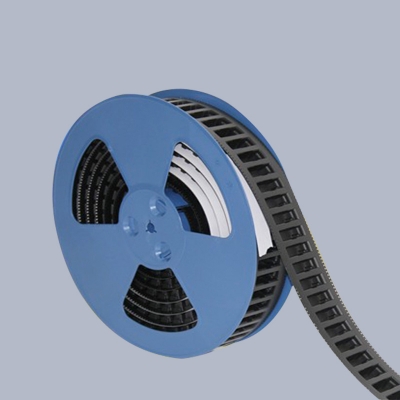

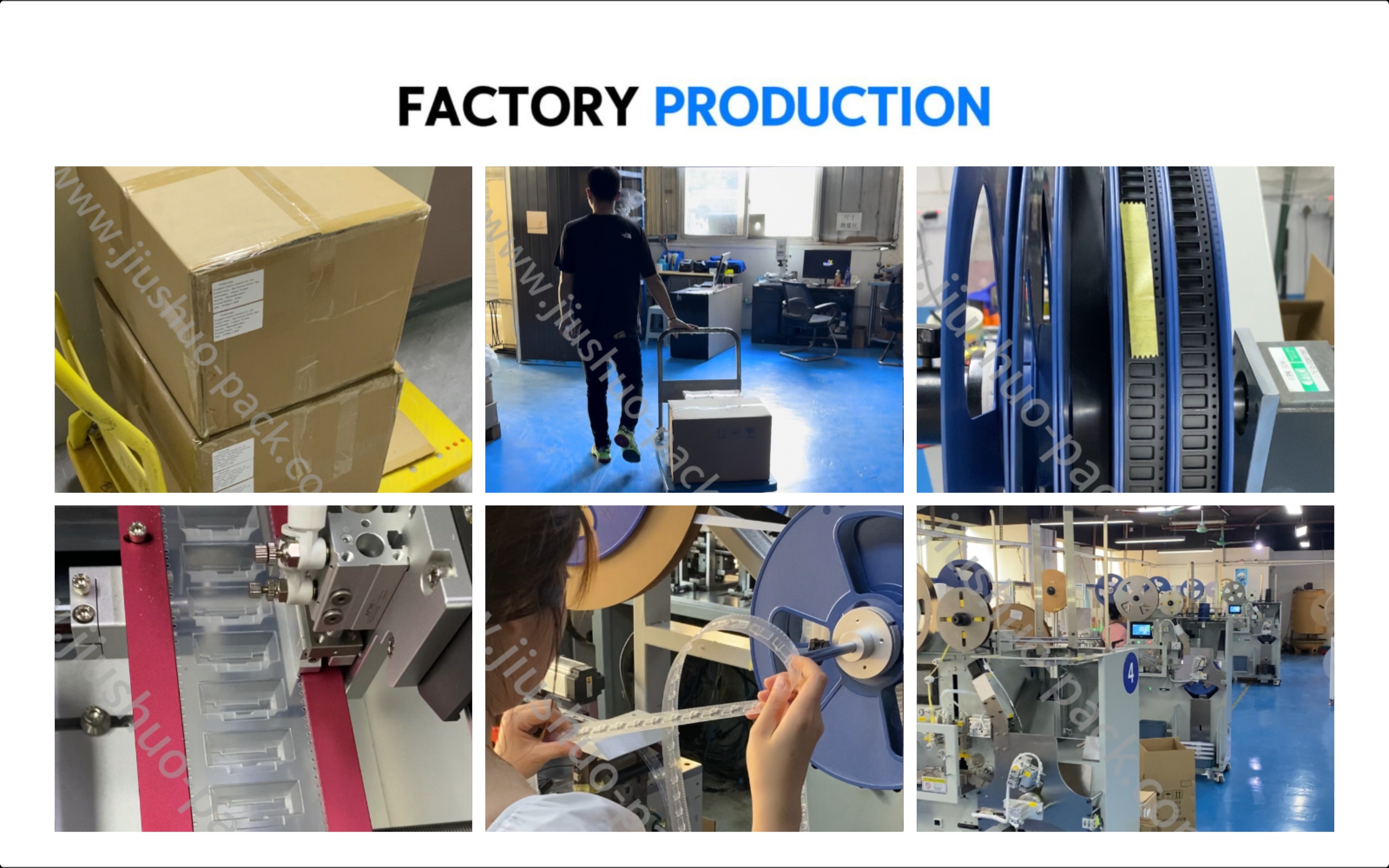

Intelligent production improves efficiency and reduces "labor costs". Traditional tape production relies on manual winding and counting, which not only has a slow speed but also often causes loose rolls and shortage of quantity due to operational errors, resulting in increased rework costs. jiushuo equips an intelligent winding machine, making the entire process from tape formation to winding and packaging fully automated. Not only does it increase the daily production volume of a single production line from 8,000 meters to 15,000 meters, but it also eliminates 70% of manual operations. Combined with a 24-hour non-stop production mode, the order response speed is 30% faster than the industry average. Even for urgent orders, there is no need to pay "rush fees". A customer in the Pearl River Delta region calculated that after switching to jiushuo‘s tape, for a single batch of 50,000 meters of orders, the cost transfer of the labor cost alone saved nearly 2,000 yuan.

Three factory locations reduce "logistics costs" by half. Although the tape is light, the number of rolls is large, and the freight and time costs of long-distance transportation are often overlooked. jiushuo has set up factories in Vietnam, Chengdu, and Dongguan simultaneously, forming three service circles in "South China, Southwest China, and Southeast Asia": Customers in the Pearl River Delta region receive shipments from the Dongguan factory and receive them the same day; orders from the Chengdu region are taken by the Chengdu factory, and the logistics cost is 40% lower than shipping from the coast; the Vietnam factory covers customers in Southeast Asia, not only avoiding the risk of cross-border logistics delays but also saving some customs duty costs. A certain automotive electronics manufacturer in Chongqing reported that before purchasing tapes from the east coast, each batch of freight was 1,200 yuan. After switching to the supply from jiushuo‘s Chengdu factory, the freight was directly reduced to 500 yuan, and the logistics cost alone saved nearly 8,000 yuan in a year.

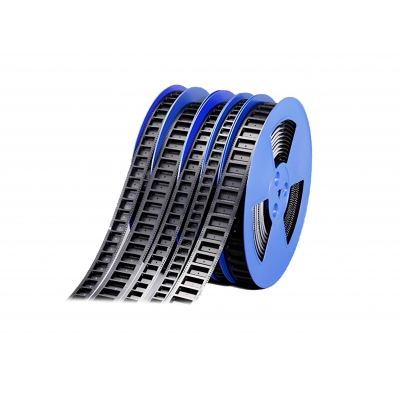

Sufficient inventory to guarantee, eliminating the "emergency cost" trap. When there is a sudden shortage of materials during the peak production season, temporarily finding a manufacturer to replenish is not only 30% higher in quotation but also may be delayed by logistics, resulting in production line shutdown - this is the most troublesome "hidden cost" for the purchasing party. jiushuo has established a reserve warehouse for raw materials of common specifications of tapes, such as 0805 resistors and SOP8 chip tapes, and they can be dispatched at any time; even for non-standard customized models, they will reserve spare production capacity based on the customer‘s historical orders. Last year, a mobile phone manufacturing factory urgently needed 12,000 rolls of special-shaped tapes due to a sudden order. The reserve in the Dongguan factory of jiushuo directly met the demand, not only not charging rush fees but also avoiding a 50,000-yuan loss caused by 4 hours of production line shutdown.

More importantly, jiushuo‘s "cost reduction" is never at the expense of quality. Multiple factories implement unified quality control standards, regardless of where the shipment is from, the cavity size and tensile strength remain consistent.

For the purchasing party, the real "cost saving" is not buying low-priced products, but choosing a partner that can help you control the full-chain cost. jiushuo‘s intelligent production, regional advantages, and sufficient inventory are like adding three layers of insurance for costs - such tapes are truly "cost-effective".