Classification of Carrier Media

The classification of carriers is based on the characteristics of electronic components and the requirements of the production process, and is divided from different dimensions - the aim is to ensure that each type of component can be matched with the most suitable "packaging container".

The following are the most common three classification methods:

1. Classification by material (the most basic classification method)

The material of the carrier directly determines its protective ability and applicable scenarios:

Plastic carrier tape (main type)

This is the most commonly used carrier tape in the electronics industry. The common materials include three types:

PS Carrier: Low cost, easy to shape, suitable for common resistors, color-coded inductors, etc., which are small and lightweight conventional components. It is the most cost-effective option.

PC Carrier: Strong toughness, good impact resistance, can be adapted to slightly larger-sized components (such as over 5mm) or slightly heavier components (such as small connectors), and is not easily damaged by external force.

PET Carrier: Resistant to high temperatures and chemical corrosion, can withstand the "reflow soldering process" in electronic assembly, suitable for precision components such as chips and ICs that require furnace welding.

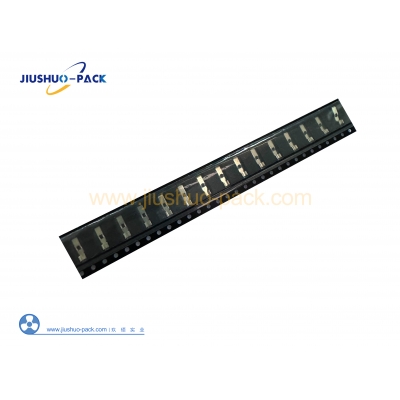

The picture below shows the transparent PET material carrier and the black PS carrier.

Paper tape

Environmentally friendly and extremely cost-effective, but with poor moisture resistance and impact resistance, it is only suitable for lightweight and basic components with low protection requirements (such as ordinary carbon film resistors). Currently, its application scope is relatively narrow.

2. Classification by Function (For Special Requirements)

The core is to address the "enemy" of electronic components, namely "static electricity":

Conductive tape (anti-static tape)

Adding conductive agents to the plastic material enables rapid elimination of static electricity, preventing static electricity from damaging sensitive components such as chips and sensors - it is the "standard packaging" for high-end electronic components in mobile phones and computers.

Non-conductive carrier tape

Without anti-static function, it is cheaper in cost and is only suitable for ordinary components that are not afraid of static electricity (such as ceramic capacitors).

Different types of carrier tapes are essentially designed to precisely match the requirements of different parts, so that these tiny components can be safely and efficiently transported and assembled.

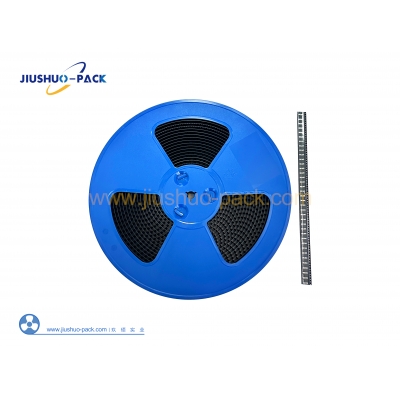

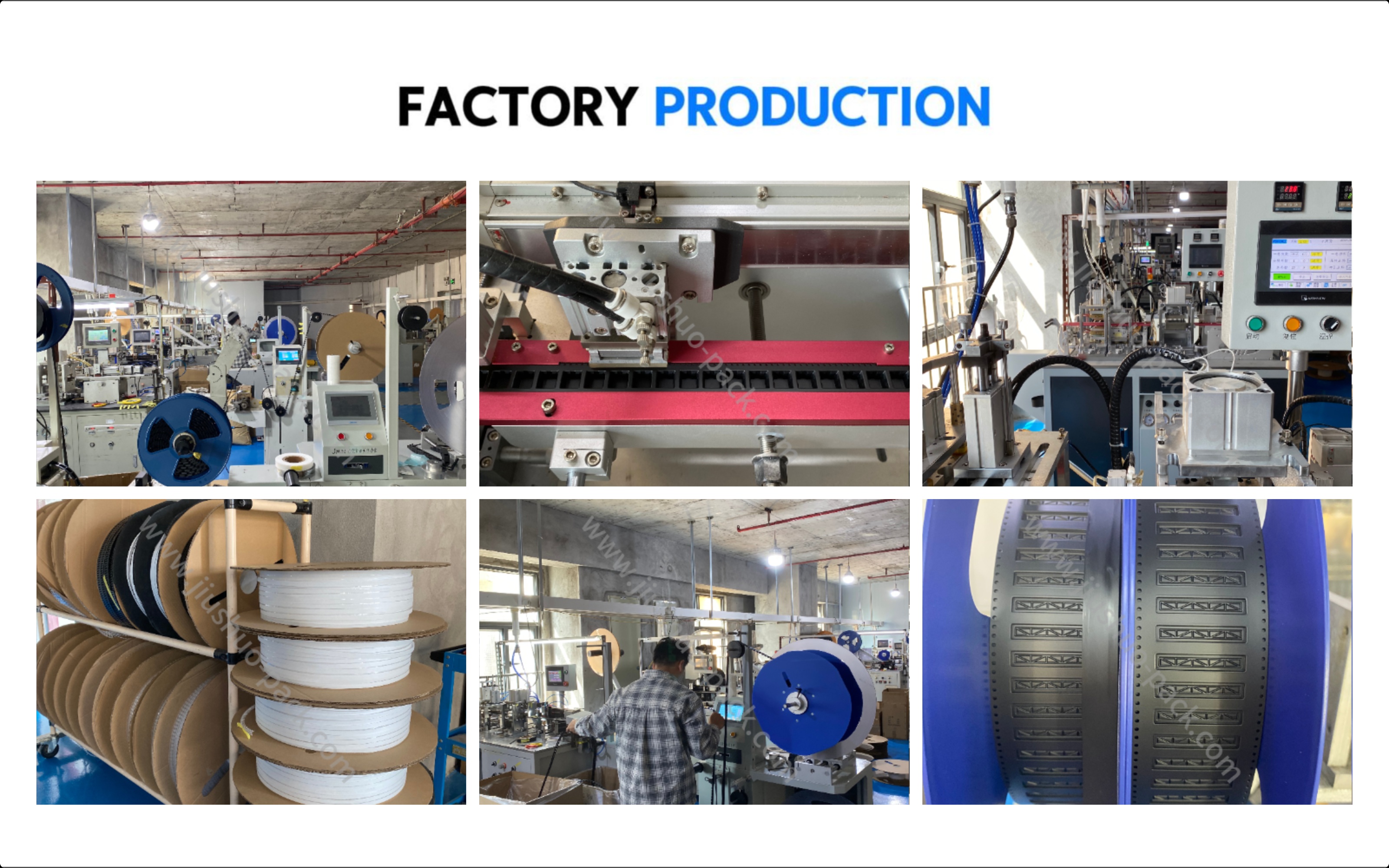

At the present Jiushuo carrier tape factory, all the above types of carrier tapes have high quality, good service, low unit price, and can fully meet your needs. If you need special non-standard carrier tapes, Jiusuo can also customize according to your requirements.

Confirmation of the drawing to mold release and sample delivery is completed in the shortest time of only 4 hours!