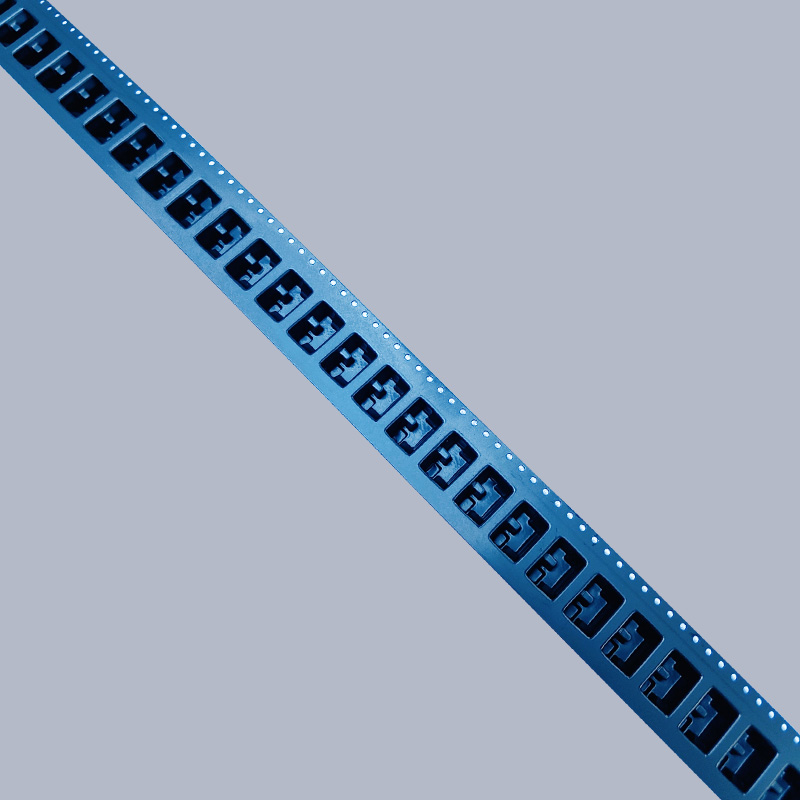

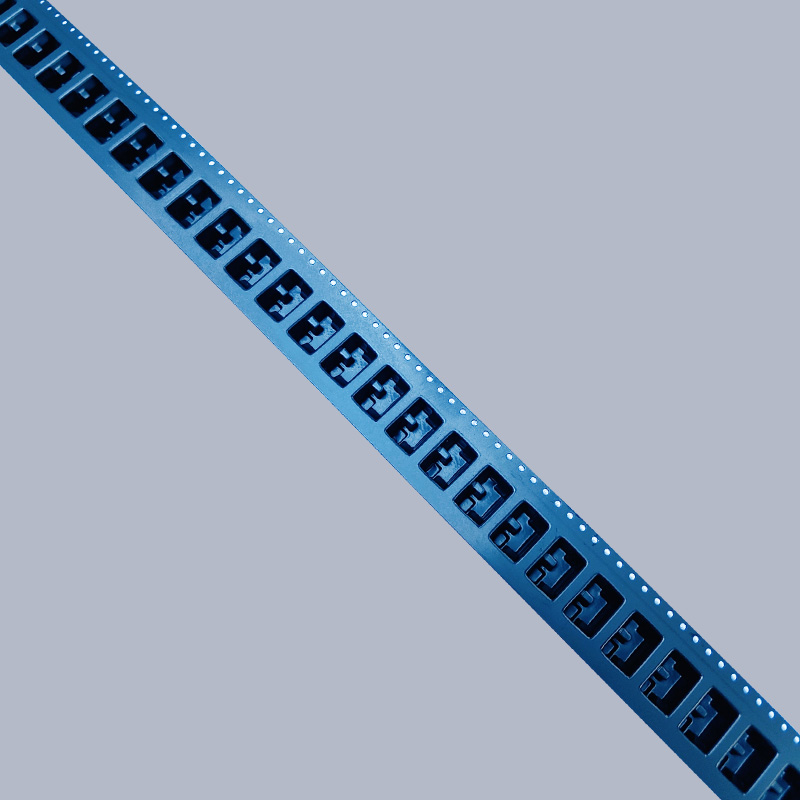

China Jiushuo Carrier Tape-Analysis of the main reasons for the small E value of carrier tape

:2024-10-11

:337

During the debugging of tape production, a small E value is a very common problem. What are the main causes of this problem? After analyzing and summarizing, the following main reasons are obtained:

1. Poor positioning of the punching die is the most common defect in tape production. If the punching die is misaligned, meaning that it is not aligned with the guide rail, it can cause the E value of the tape to be too small. If the punching die is positioned too far back, not in contact with the punching die, the punching pin may hit the edge of the tape, also causing the E value to be too small. Therefore, it is important to properly position the punching die.

2. If the slit is not opened on the non-die blade, changes in the position of the die blade or the fixed plate of the punch will result in an unadjustable process, causing the E value to be too small.

3. The side pressure head crushes the edge of the raw material, causing the edge to bulge. When the raw material enters the mold, the bulging area will cause the raw material to not be close to the mold, resulting in a smaller E value for the carrier tape.

4. shrinkage of the carrier tape or bending of the raw material may also cause the E value of the carrier tape to be smaller.

5. if there is debris in the die guide groove, causing the die guide groove to be scratched, this will also easily result in a smaller E value for the carrier tape.

In summary, during the debugging process of tape production, we should pay attention to dealing with the above issues and try to avoid a small E value of the tape to ensure the quality and stable production volume of the tape.