-

Embossed carrier tape packing material

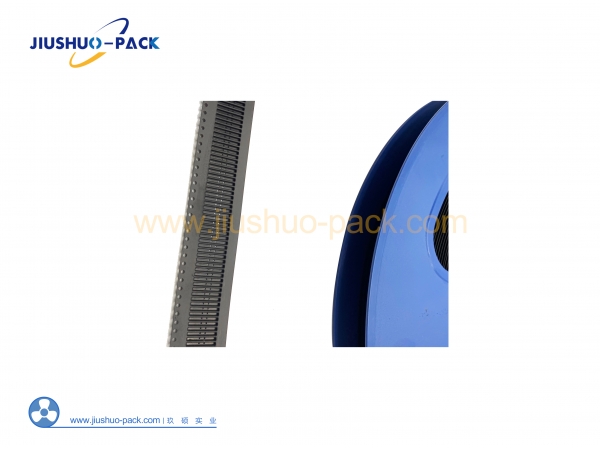

The production process requirements for carrier tape packaging materials: The carrier tape must have an isolation tape present throughout its production and forming process until the material is collected in a reel. What is the purpose of the isolation tape in the carrier tape production process? After the carrier tape is produced, it needs to be collected on a reel. The collection process requires that the carrier tape and isolation tape be collected simultaneously. Since the carrier tape is a plastic sheet material with pockets, when it is wound into a roll, the formed part will overla...2025-02-24 -

Material of embossed carrier tape

The material of the carrier tape mainly includes two categories: plastic (polymer) and paper. Embossed carrier tapes are mainly made of plastic materials, and the mainstream in the market is PC (Polycarbonate) carrier tape, PS (Polystyrene) and ABS (acrylonitrile-butadiene-styrene copolymer resin) carrier tape. In addition, there are also a small number of carrier tapes made of PET, APET and other materials. Punched carrier tapes are mainly made of paper or PE composite materials....2025-02-22 -

Embossed carrier tape molding introduction

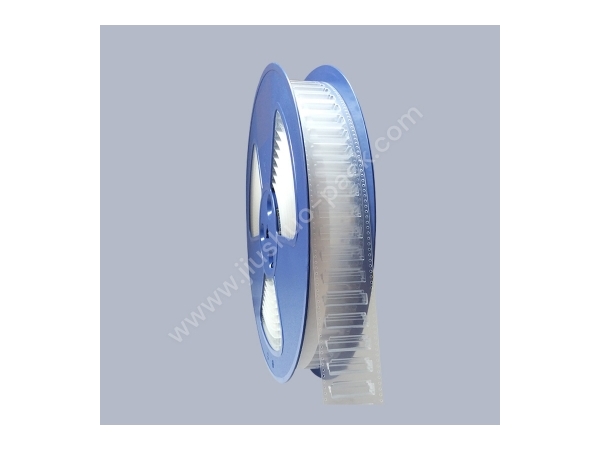

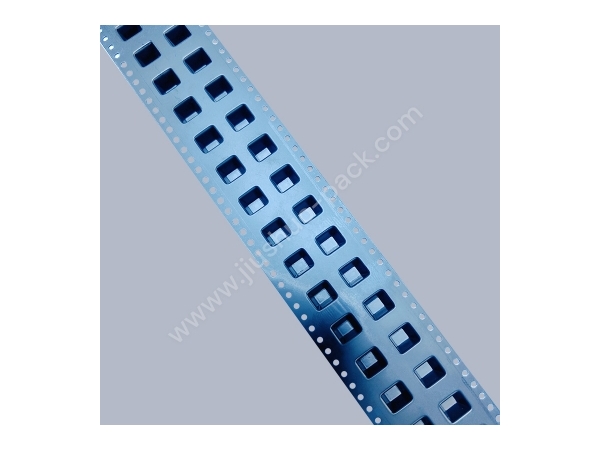

By the molding characteristics of the pockets, carrier tapes can be divided into embossed carrier tapes and punched carrier tapes. An embossed carrier tape is a type of carrier tape in which the material of the carrier tape is locally stretched or suction-formed to create a recessed pocket shape by die stamping or blister method. This type of carrier tape can be molded into pockets of different sizes to accommodate the size of the electronic components to be packaged. A punched carrier tape is a type of carrier tape in which pockets are formed by punching through or partially through the c...2025-02-21 -

The specification of the embossed carrier tape

According to the size of the electronic components carried by the package, the carrier tape is also divided into different widths. Common widths are 8mm, 12mm, 16mm, 24mm, 32mm, 44m, 56mm and so on. With the development of the electronic market, chips are becoming smaller and smaller, and the carrier tape is also developing correspondingly in the direction of precision, and so far there is already a 4mm width carrier tape supply on the market.In order to protect electronic components from electrostatic damage, some precision electronic components have clear requirements for the antistatic ...2025-02-15 -

Use of embossed carrier tape

Carrier Tape refers to a strip product used in the field of electronic packaging, which has a specific thickness and is equidistant in its length direction with holes (also known as pockets) for placing electronic components and location holes for index positioning.Carrier tape is mainly used in the electronic component mounting industry, which is used in conjunction with cover tape to carry and store electronic components such as resistors, capacitors, transistors, and diodes in pockets on the carrier tape. The electronic components are protected from contamination and damage during trans...2025-02-14 -

8-104mm PS&PET&PC material with anti-static and non-anti static type

There are many existing molds for conventional universal components,and we can design carrier tapes according to customers’ components samples,which are with accurate dimensions and meet the requirement of EIA-481. We can machine-shaping different types of carrier tapes,with ordinary type and anti static type .We can also design molds according a quite mature stage through years’ accumulation.Now the quality of our products can absolutely meet customers’ requirements,and are widely used in different areas such as inductance, connector, IC, resistor, capacitor, switch, fuse, transfo...2024-11-23 -

tape and reel packaging

As an electronic packaging material, few people in China have conducted environmental tests on carrier tape, and it can even be said that little is known about it. In China, it is generally believed that carrier tape packaging materials are only used for packaging, and passing SGS is no problem. However, little attention has been paid to the fact that carrier tape products will change in different environments and affect the packaging materials. Therefore, it is necessary to launch an environmental monitoring plan for carrier tape packaging as soon as possible to standardize carrier t...2024-11-21 -

Embossed Carrier Tape And Cover Tape Factory

Carrier tapes are mainly used in the electronic component mounting industry. They are used in conjunction with cover tape (upper sealing tapes) to carry and store electronic components such as resistors, capacitors, transistors, diodes, etc. in pockets on the carrier. The pockets are sealed by closing the cover tape above the carrier to form a closed package, which is used to protect electronic components from contamination and damage during transportation. When electronic components are mounted, the cover tape is peeled off, and automatic mounting equipment uses the precise positioning of...2024-11-20 -

China JiuShuo Embossed Carrier Tape Manufacturers

The automation of the carrier tape in the electronic industry is an inevitable trend in the current era of labor shortages. In this context, automation becomes increasingly important, thereby forcing the transformation of manual labor to automation. The opportunities in the carrier tape industry have thus arisen, as the use of large-scale carrier tape reduces labor costs and improves speed, which is a good thing for factories. Nowadays, no matter what industry it is, electronic hardware or others, all are striving to change and adapt to the needs of carrier tape production, which can also...2024-11-19 -

China Embossed Carrier Tape Factory

Precision tape carriers are mainly used for surface mounting of downstream electronic components, and can be widely used in ICs, resistors, inductors, capacitors, connectors, fuses, switches, relays, connectors, oscillators, diodes and other electronic components. As the types, size and performance of downstream electronic components are continuously upgraded and optimized, the precision tape carrier system used for them is also constantly developing and innovating. Electronic component precision carrier tape, according to the material used, is mainly divided into paper carrier tape and...2024-11-18 -

Carrier Tapes- JiuShuo

A precision carrier tape is a strip-shaped product used in the field of electronic packaging, which has a specific thickness and evenly distributed holes (also known as pockets) for holding electronic components along its length. It is mainly used in the industrial application of electronic component mounting, where it is used in conjunction with tape or cover tape to carry and collect a series of small electronic components such as resistors, capacitors, transistors, and diodes, and package them in the pockets of the thin carrier tape. The precision carrier tape is then sealed with the tap...2024-11-18 -

JiuShuo Carrier Tape Materials

The embossed carrier tape material is mainly composed of plastic materials, with the mainstream in the market being PS(Polystyrene) and PC (Polycarbonate)ABS (acrylonitrile butadiene styrene copolymer resin), in addition to a small amount of PET, APET and other materials made of carrier tapes。 All products comply with EIA-481-D and ROHS standards, and non-standard embossed carrier tapes can also be customized。...2024-11-16