Product Model: JSTW-ZDJ-021

Product Name: Embossed Carrier Tape Forming Machine

Efficiency: 200 to 300 meters can be produced per hour

Product application: Production of embossed carrier tape

Equipment description

The main body of the carrier tape forming machine can produce carrier tapes with a width of 12 to 88 millimeters, with a stable production speed of 200 to 300 meters per hour (the production capacity varies depending on the thickness of the raw materials and the size of the product cavity). It is suitable for raw materials such as PS, PET,and PC. The tape winding device can wind super-large reels with a diameter of over 1 meter.

Performance features

The machine adjustment performance is excellent. The mold installation, mold removal and adjustment methods are simple and convenient. The adjustment technician can completely adjust the heating, forming and punching molds in one step from the front of the forming machine. The adjustment time is shortened to within 1 hour,and the mold adjustment efficiency is significantly improved. It adopts a direct servo motor pull belt device to ensure precise accuracy.It is small in size and has a compact and reasonable overall structure.The system adopts a user-friendly touch screen control. The control panel is placed independently, which is convenient for technicians to operate and fully considers ergonomics.

Function

· Forming carrier tape range: Carrier tape with a width of 12mm-88mm(customizable)

· Forming methods: heating, forming, punching, drawing, cutting

· Pull belt method: Servo pull belt

· Punching method: Cylinder

· Operation mode: Touch screen

· Counting method: Count by module

· Adjustment method: Micrometer

Main configuration

· Control Unit: Mitsubishi PLC (Japan)

· Display unit: Display and control touch screen (domestic)

· Pull band unit: Panasonic servo motor (Japan)

·Temperature control unit: High-precision PID temperature controller(RKG)

· Pneumatic unit: Long-life cylinder (Taiwan Airtac)

The above configuration can be adjusted according to customer requirements (the standard configuration may be upgraded with performance changes, and the configuration of the shipped equipment shall prevail).

Parameter

· Power supply: AC220V, 50Hz

· Power consumption: 3kw

· Air pressure: 5 to 7kg

· Temperature control range: Room temperature to 300℃.

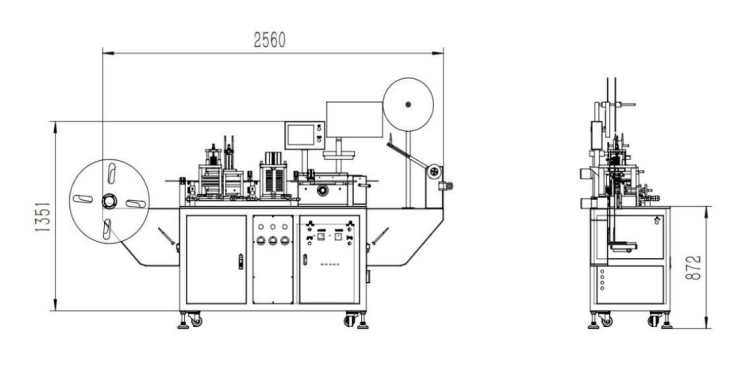

· Dimensions: L2600mm×W600mm×H1500mm

· Weight: 500KG

The diameter of the material collection coil is 13 inches /22 inches

The diameter of the discharge reel is 22 inches

The above parameters can be adjusted according to the customer‘s requirements (standard parameters may be upgraded for performance changes, with the configuration of the shipped equipment as the standard).

Overview of Engineering personnel

"Spot supply"

· Excellent and stable forming structure: After years of improvement and practice. This mechanism is easy to operate and stable.

· Superior performance servo motor.The all-steel structure body, combined with high-precision machining,makes the equipment more durable.

· Simple and mature operation procedures and interfaces

All the processing accessories are independently processed by our company‘s milling machines, grinders and wire cutters.To ensure good quality and equipment cost

| File Name : | Format: | Size: | Download: |

|---|