Tape tension: What is it?

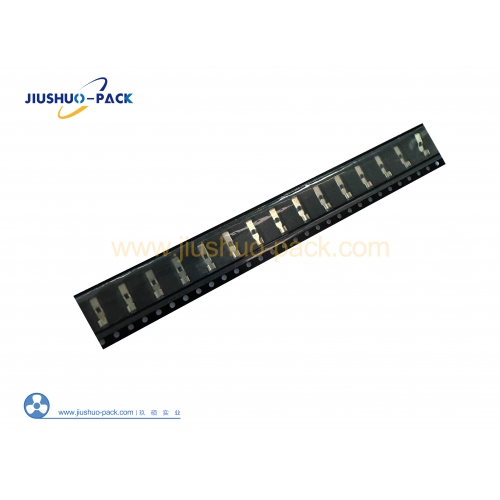

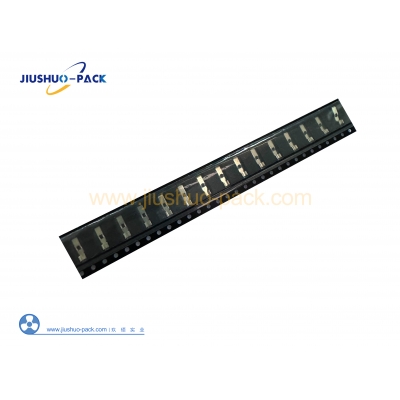

In front of the automated production lines in electronic factories, you often see a scene: machines steadily tear open the cover tape of the carrier tape and precisely take out the chips and resistors inside. Behind this, it all depends on the "carrier tape tensile force" to "back it up". It may seem like a small parameter, but it directly determines whether the parts can be safely transported and whether the production can proceed smoothly. Please provide the text you would like translated.

1. Tensile force of carrier tape: It‘s not about "the tighter, the better" adhesive strength

The tensile force of the carrier tape is essentially the adhesive strength between the cover tape and the base tape (the main part of the tape with cavities) - just like installing a "sticky door" for the "small house" of the components, the tensile force is the tightness of the fit between the "door" and the "house". Please provide the text you would like translated.

Its core function is "balance":

If the pulling force is too small, the cover tape may come loose. During transportation, dust and moisture can seep into the mold cavity, potentially causing the parts to become contaminated or fall out, resulting in direct scrapping. Please provide the text you would like translated.

Excessive pulling force: When the automated equipment tears the carrier tape, it will be "difficult", either breaking the carrier tape or pulling out the parts along with it, causing the production line to jam. Please provide the text you would like translated.

Qualified tensile strength: It can make the cover tape "stick firmly and tear smoothly", remain tight during transportation, and be torn off at a uniform speed when the machine takes the parts without damaging the components. Please provide the text you would like translated.

The most similar example in life is the sealing tape of express delivery boxes - if it‘s stuck too loosely, it will come off; if it‘s stuck too tightly, it will tear the box when you try to remove it. The logic of the tensile force of the carrier tape is exactly the same. Please provide the text you would like translated.

II. How Do Enterprises Control the Tensile Force of Carrier Tapes? 3 Core Steps + Practical Operations

The key to an enterprise‘s control over tensile force lies in "setting standards, frequent testing, and process control", and each step must align with production and customer requirements:

1. First, define the "qualified tensile force range": precisely demarcate based on usage scenarios.

Different carrier tapes and different components have completely different tensile force standards. Enterprises will first clarify the "red line":For precision components (such as chips, sensors): the tensile force should be controlled within 0.5-1.5N (Newtons), with a force similar to gently pulling an A4 paper, to avoid vibration damage to the components when tearing the cover tape. Please provide the text you would like translated.

2. Real-time control during production: Starting from the "bonding stage" to address the root cause

Just like when applying express delivery tape, if the pressure and speed of movement are too random, it will lead to uneven adhesion. Enterprises will use automated equipment to fix these parameters to avoid human errors. Please provide the text you would like translated.

3. Stringent pre-shipment testing: Sampling inspection + Data traceability

Summary:

The tension of the carrier tape is not an "abstract force", but a "key indicator" that directly affects the safety of components and production efficiency. The control logic of enterprises is simple: first, set the tension standard according to actual needs, then control the source parameters from the production bonding process, and finally use professional testing to ensure quality before leaving the factory. In essence, it is to make the "door of the small house of the component" stick just right, protecting the component while not hindering the factory‘s work.

At the Jiushuo factory, the quality control department currently has professional tensile strength testing equipment. From raw materials to production and to the finished products, tensile strength is strictly controlled at every stage to eliminate all potential risks and ensure the strength of each batch of your products. Please provide the text you would like translated.