Non-standard Carrier Tape: The "exclusive movers" of high-end manufacturing

Today‘s electronic components are getting smaller and their shapes are becoming more and more unique. As a result, those common "standard carriers" are gradually no longer sufficient.

At this point, "customized non-standard tapes" that can be tailored as needed have become a necessity for high-end manufacturing.

They are not bound by fixed standards and are specifically designed to meet special requirements. They are also the key to differentiating the advantages of tape manufacturers.

The customization of non-standard tape permeates every aspect.

For example, for ultra-small components with dimensions of 150 micrometers by 75 micrometers, a carrier tape with a width of 3 millimeters can be produced. The "small pocket" for holding the components is only 0.18 millimeters by 0.09 millimeters, with an error of no more than 0.02 millimeters.

When dealing with irregularly shaped sensors, we design grooves with positioning protrusions to ensure that the components do not shake more than 0.05 millimeters.

The material can also be selected flexibly. For use in cars, we choose a high-temperature-resistant material that can withstand temperatures ranging from -40°C to 260°C.

For medical use, use environmentally friendly materials without harmful substances, and they can also pass medical-grade certification. Even chips can be added for full traceability, or protective coatings can be applied to prevent the precision components from being scratched.

Of course, there are some minor drawbacks to customization. It takes 2 to 4 weeks to create the mold, and the cost will be higher for small production runs.

But it can solve the major problems in high-end manufacturing!

A domestic enterprise has developed a battery chip carrier for new energy vehicles using a combination of "PET + conductive coating + heat-resistant adhesive". This has increased the success rate of the pick-up operation of the assembly machine from 98.5% to 99.9%, and the daily output of the production line has also increased by 20%. Currently, in the high-end fields such as semiconductors and automotive electronics, the market share of non-standard carriers has exceeded 40%.

As the "pioneer" of technological upgrades, non-standard belts not only can meet high-end demands, but also can, in turn, drive the progress of standard belts. As components become increasingly refined in the future, it will also continuously break through in terms of precision and functionality, serving as the "microscopic cornerstone" for precise manufacturing.

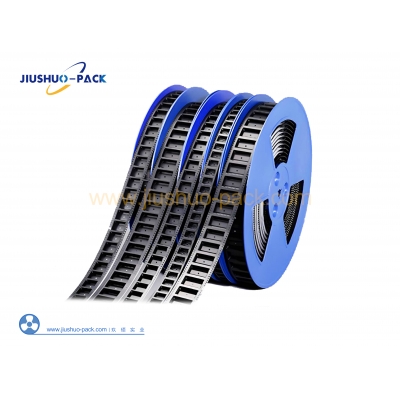

Jiusuo Factory not only focuses on standard carrier tapes but also has extensive experience in non-standard carrier tapes.

If your tape is unique, contact Jiushi. They can design the perfect solution for you!