Tape problems keep popping up? Jiu Shuo will solve them for you once and for all.

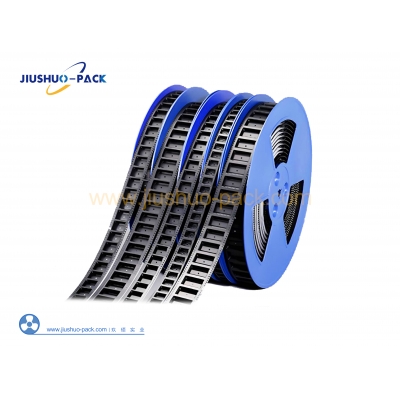

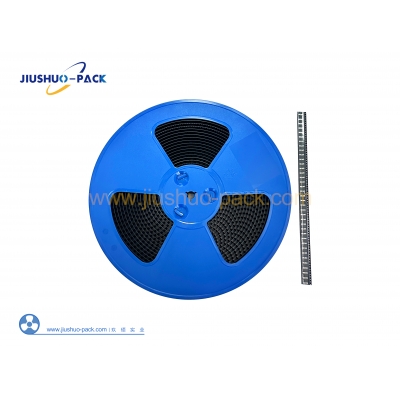

Friends in the electronics manufacturing industry all know that although tape is small, it can directly affect the efficiency of the entire production line. Static electricity damaging chips, pick-and-place machines getting stuck, and poor sealing of cover tape... We at Jiu Shuo have encountered all these problems while serving thousands of customers. But don‘t worry. As a supplier with years of experience in the tape industry, we have solved these problems at the source, allowing you to use tape with peace of mind.

Problem 1: Static electricity "sneaks up" on components, causing losses

[Customer Experience] A consumer electronics manufacturer in Shenzhen previously used tapes from small factories. After a batch of chips were mounted, the failure rate was as high as 15%. It turned out that static electricity was the culprit, resulting in a direct loss of several thousand dollars. After switching to Jiu Shuo‘s tapes, they never had such problems again.

[Jiu Shuo‘s Solution] Our tapes strictly control the anti-static performance from the raw materials. The surface resistance of the standard model is stable at 10^9 to 10^11 Ω, and the special model for chips reaches the permanent anti-static standard of 10^6 to 10^8 Ω. Before each roll is shipped, it undergoes random inspection with a surface resistance tester and comes with a test report. You can use it directly after receiving the materials without the need for secondary inspection. Even if the humidity in the workshop is difficult to control, our anti-static coating has been specially treated and will not fail due to environmental fluctuations.

Problem 2: Pick-and-place machines frequently get stuck, halting production for half a day

[Customer Experience] An automotive electronics factory in Dongguan once had to stop the pick-and-place machine every hour due to burrs in the tape‘s perforations and inaccurate pocket spacing, reducing daily production capacity by 30%. After contacting us, the number of stops dropped to zero on the first day they tried Jiu Shuo‘s tapes.

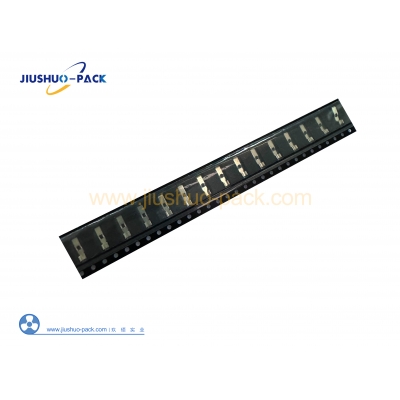

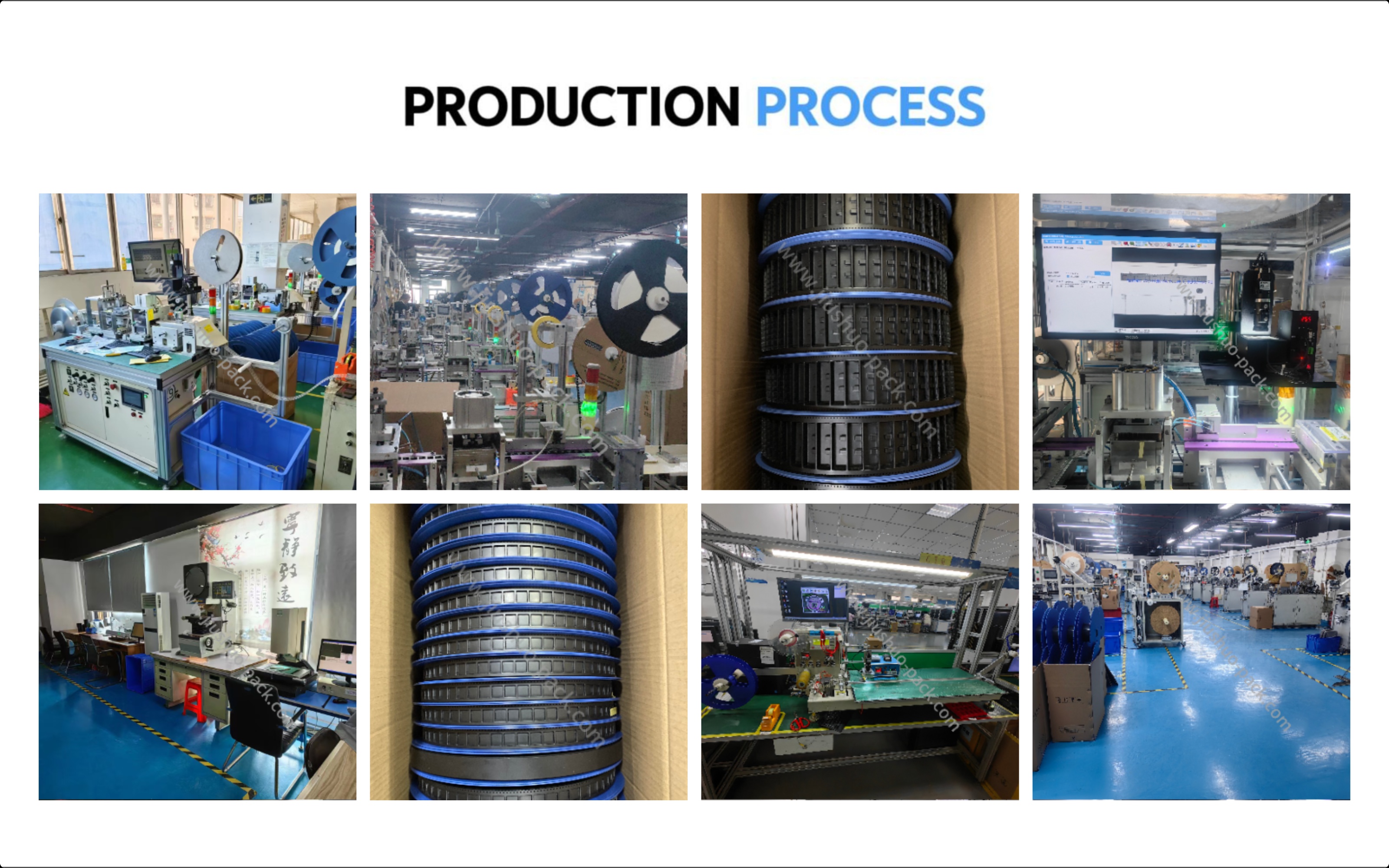

[Jiu Shuo‘s Solution] We have a dedicated precision mold room. The perforations are processed using nanometer-level engraving technology, ensuring smooth edges without burrs. Pocket dimensions are monitored in real time by a two-dimensional image measuring instrument, with spacing errors controlled within ±0.02mm, which is stricter than the national standard.

Problem 3: Cover tape is "uncooperative", causing parts to fall out and being difficult to tear

[Customer Experience] Mr. Li, who runs a sensor factory in Suzhou, was previously troubled by cover tape issues: either it didn‘t seal tightly, causing parts to fall out during transportation, or it stuck too firmly, deforming the tape when the pick-and-place machine tore it. After customizing tapes with us, all these problems were resolved.

[Jiu Shuo‘s Solution] We will first ask about your cover tape type and pick-and-place machine model, and precisely match the heat-sealing parameters for the tape. PET material is suitable for 120°C to 140°C, and PP material is suitable for 100°C to 120°C. We will also provide a dedicated heat-sealing parameter table. Even more considerate is that before bulk supply, we will send a 10-meter sample for you to test the sealing. Only after confirming the effect will we proceed with production, so you don‘t have to worry about any issues during the process.

In Jiu Shuo‘s view, a good carrier tape not only needs to be of high quality but also offer excellent service. From parameter customization, sample trials to after-sales guidance, we meticulously handle every step to ensure you have no worries when using the carrier tape. Consult now and you can get a free customized carrier tape matching solution to make your production more efficient!