-

Embossed Carrier Tape Manufacturers China JiuShuo

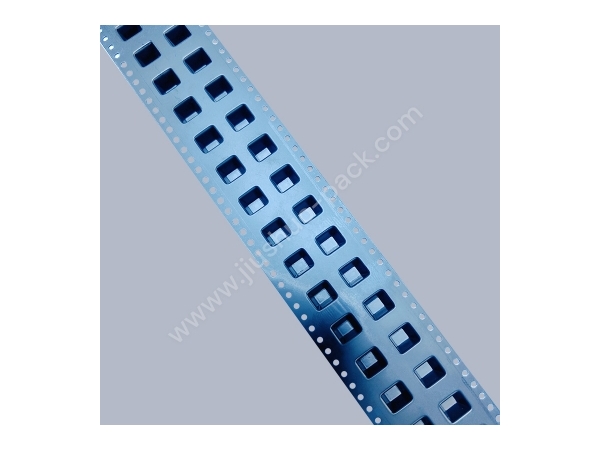

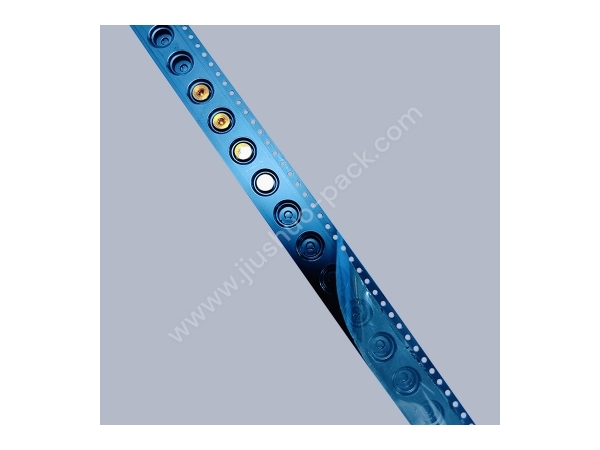

Carrier tapes can be divided into embossed carrier tapes and punched carrier tapes. An embossed carrier tape is a type of carrier tape in which the material of the carrier tape is locally stretched or suction-formed to create a recessed pocket shape by die stamping or blister method. This type of carrier tape can be molded into pockets of different sizes to accommodate the size of the electronic components to be packaged. A punched carrier tape is a type of carrier tape in which pockets are formed by punching through or partially through the carrier tape using a mold. This type of carrier...2024-10-23 -

PS Embossed Carrier Tape 8-104MM

According to the size of the electronic components carried by the package, the carrier tape is also divided into different widths. Common widths are 8mm, 12mm, 16mm, 24mm, 32mm, 44m, 56mm and so on. With the development of the electronic market, chips are becoming smaller and smaller, and the carrier tape is also developing correspondingly in the direction of precision, and so far there is already a 4mm width carrier tape supply on the market.In order to protect electronic components from electrostatic damage, some precision electronic components have clear requirements for the antistatic ...2024-10-22 -

Embossed Carrier Tape- JiuShuo

Carrier Tape refers to a strip product used in the field of electronic packaging, which has a specific thickness and is equidistant in its length direction with holes (also known as pockets) for placing electronic components and location holes for index positioning.Carrier tape is mainly used in the electronic component mounting industry, which is used in conjunction with cover tape to carry and store electronic components such as resistors, capacitors, transistors, and diodes in pockets on the carrier tape. The electronic components are protected from contamination and damage during trans...2024-10-22 -

The role of the cover tape

Cover tape is mainly used in electronic component mounting industry. It is used with the carrier tape, the resistance, capacitor, transistor, diode and other electronic components are carried and stored in the pocket of the carrier tape, and the cover tape is sealed above the pocket formed by the carrier tape to form a closed package, which is used to protect the electronic components from pollution and damage during transportation. When the electronic components are mounted, the cover tape is peeled off, and the automatic mounting device takes out the components in the pocket successively ...2024-10-21 -

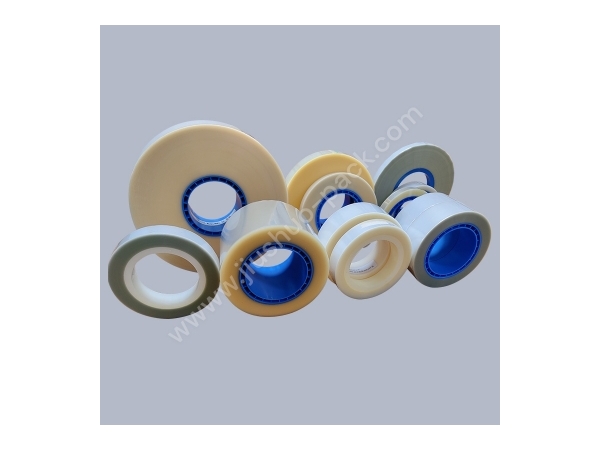

JiuShuo Cover Tape

Cover tape refers to a strip product used in the field of electronic packaging, used in conjunction with the carrier tape. The cover tape is usually based on polyester or polypropylene film, and is composite or coated with different functional layers (antistatic layer, adhesive layer, etc.), which can be sealed on the surface of the carrier tape under external force or heating to form a closed space and protect the electronic components in the carrier pocket....2024-10-21 -

Advantages of PET carrier tape

High strength and good flexibility: PET strapping is a plastic strap, but it combines the strength of steel strapping and the toughness of PP strapping. PET strapping overcomes the weakness or brittleness of traditional packaging material. It can maintain a 5% tightening force for a long time, not only not loosening, but also has a 5% cushioning stretch under strong external force. Its tensile strength is twice that of PP strapping. High safety: PET strapping does not have the sharp edges of steel strapping and will not scratch the packaged goods or hurt the hands. It can be ...2024-10-19 -

Electronic carrier tape

The material of the electronic carrier tape includes: PS, PET, and PC, which have different material properties. We provide suitable materials according to the different requirements of customers. The width of the electronic carrier tape is: The width of the product can be made 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, 72mm, 88mm, 106mm; the thickness is 0.3mm, 0.35mm, 0.4mm, 0.5mm, 0.6mm, etc. The product fully complies with the RoHS standard, quality assurance, and fast delivery. The color of the electronic carrier tape is: black and transparent. The thickness of the electron...2024-10-19 -

China JiuShuo Carrier Tape And Cover Tape

The carrier tape package is only one half of the carrier tape packaging system, and the other half consists of the cover tape. The carrier tape carries the electronic parts, and the cover tape seals and protects them, thus forming a complete carrier tape system. The cover tape is divided into heat-sealed cover tape and self-adhesive cover tape. The so-called heat-sealed cover tape relies on heating to seal and pack the carrier tape, while the self-adhesive cover tape relies on the viscosity of themself to seal and pack the carrier tape. The relationship between carrier tape and cover tape...2024-10-18 -

Welcome To JiuShuo Carrier Tape and Cover Tape

We have implemented lean production within the company, where we strictly control every detail of the tape production process to ensure that our products do not encounter any problems during production or that any issues that arise during production are promptly resolved to maintain our reputation for quality in the eyes of our customers. Since implementing lean production, all employees at JiuShuo Tape have taken action and regard quality as their top priority, strictly controlling every step of the tape production process to ensure the production of high-quality tape. The activity has ...2024-10-18 -

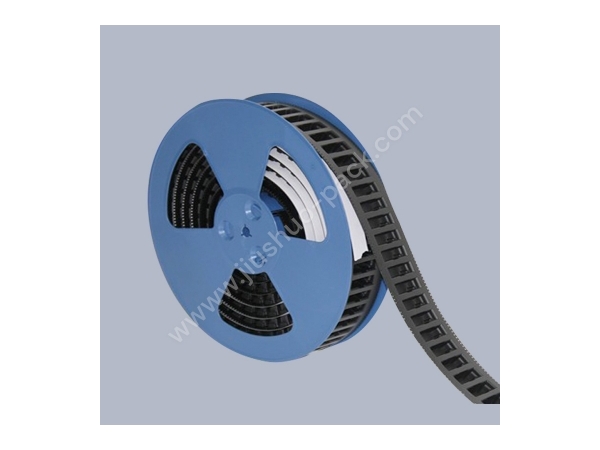

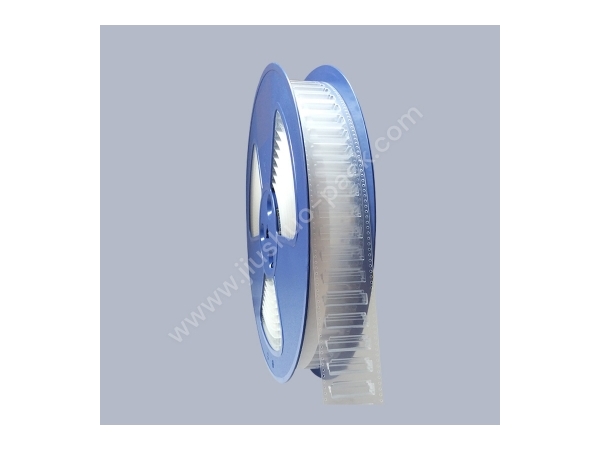

Carrier tape reel‘s pressure test

The carrier tape reel is a type of tape reel used to carry the carrier tape, as it carries the packaging items of the carrier tape, the carrier tape reel is subjected to various forces in transportation and other environments, including tensile force. In order to ensure that the carrier tape reel can withstand the pressure during production, transportation, or handling, and ensure that the carrier tape products are not damaged, the carrier tape reel must be able to withstand a certain force value to ensure the safety of the carrier tape. The tensile test performed on the carrier tape reel i...2024-10-16 -

Carrier tapes, cover tapes and carrier tape reels

1. Carrier tapes: IC-specific carrier tapes, transistor-specific carrier tapes, SMD LED carrier tapes, SMD inductor carrier tapes, comprehensive SMD carrier tapes, SMD capacitor carrier tapes, SMT connector carrier tapes, PS carrier tapes. 2. Cover tapes: Tea color, transparent, self-adhesive, heat-sealed. (5.3mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm) 3. Carrier tape reels: Connector carrier tape reels with regular blue, blue eco-friendly, black anti-static, and heat-resistant. (7-inch, 13-inch, 15-inch)...2024-10-16 -

Carrier tapes environmental requirements

As an electronic packaging material, few people in China have conducted environmental tests on carrier tape, and it can even be said that little is known about it. In China, it is generally believed that carrier tape packaging materials are only used for packaging, and passing SGS is no problem. However, little attention has been paid to the fact that carrier tape products will change in different environments and affect the packaging materials. Therefore, it is necessary to launch an environmental monitoring plan for carrier tape packaging as soon as possible to standardize carrier t...2024-10-15

You are here:Home >> FAQ >> Company News