-

Carrier tape and cover Tape

Carrier tapes are mainly used in the electronic component mounting industry. They are used in conjunction with cover tape (upper sealing tapes) to carry and store electronic components such as resistors, capacitors, transistors, diodes, etc. in pockets on the carrier. The pockets are sealed by closing the cover tape above the carrier to form a closed package, which is used to protect electronic components from contamination and damage during transportation. When electronic components are mounted, the cover tape is peeled off, and automatic mounting equipment uses the precise positioning of...2024-10-15 -

Prospects of the Carrier Tape Industry

The automation of the carrier tape in the electronic industry is an inevitable trend in the current era of labor shortages. In this context, automation becomes increasingly important, thereby forcing the transformation of manual labor to automation. The opportunities in the carrier tape industry have thus arisen, as the use of large-scale carrier tape reduces labor costs and improves speed, which is a good thing for factories. Nowadays, no matter what industry it is, electronic hardware or others, all are striving to change and adapt to the needs of carrier tape production, which can also...2024-10-14 -

Carrier Tape of Plastic Precision

A precision carrier tape is a strip-shaped product used in the field of electronic packaging, which has a specific thickness and evenly distributed holes (also known as pockets) for holding electronic components along its length. It is mainly used in the industrial application of electronic component mounting, where it is used in conjunction with tape or cover tape to carry and collect a series of small electronic components such as resistors, capacitors, transistors, and diodes, and package them in the pockets of the thin carrier tape. The precision carrier tape is then sealed with the tap...2024-10-14 -

Carrier tape Design Specifications

Understanding the Symbols in Carrier Tape Engineering Drawings: (1) W - represents width; (2) A0 - represents the length of the trench or pit bottom; (3) B0 - represents the width of the trench or hole at the bottom; (4) D - represents the diameter of the circular edge hole; (5) D1 - represents the inner hole diameter; (6) D2: Indicates the diameter of the elliptical edge hole; (7) E - represents the distance from the horizontal bisector of the circular edge slot to the upper edge of the circular edge slot (width); (8) F - represents the distance from the centerl...2024-10-12 -

Embossed Carrier Tape- JiuShuo

1. Formula for calculating the number of marbles and the length in meters (1) The number of pieces per roll packaging = (wrapping area divided by (K0 + t) divided by P) * 0.9 (2) The number of meters wrapped per roll = (the number of pieces per roll x P) / 1000 + 1 (3) The wrapped area = πR2 - πr2 (4) The commonly used rim diameter is 13", inner diameter is 100, then the winding area is 77,677. (5) The number of pieces per roll packaging = (77677 / (K0 + t) / P) * 0.9 2. Determination of carrier tape related dimensions (1) The P-value is a multiple of 4 and great...2024-10-12 -

China Jiushuo Carrier Tape-Analysis of the main reasons for the small E value of carrier tape

During the debugging of tape production, a small E value is a very common problem. What are the main causes of this problem? After analyzing and summarizing, the following main reasons are obtained: 1. Poor positioning of the punching die is the most common defect in tape production. If the punching die is misaligned, meaning that it is not aligned with the guide rail, it can cause the E value of the tape to be too small. If the punching die is positioned too far back, not in contact with the punching die, the punching pin may hit the edge of the tape, also causing the E value to be...2024-10-11 -

Carrier tape supplier - JiuShuo

Thin carrier tape is a strip-shaped product that can package and carry electronic components. According to the base material, it can be divided into paper thin carrier tape and plastic thin carrier tape. Plastic thin carrier tape refers to a thin carrier tape made of plastic material, which has the advantages of good moisture resistance, high tensile strength, strong anti-static ability, anti-tearing, and no deformation at high temperatures, and can be used for the packaging of electronic components with a size of 1mm or more. There are various types of plastic thin carrier tapes, which ...2024-10-11 -

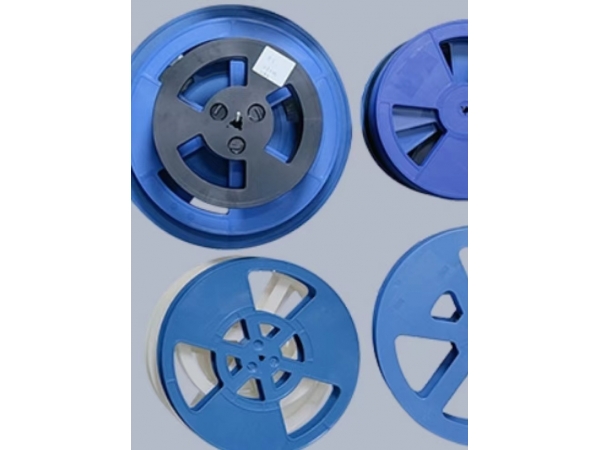

Embossed carrier tape reel

The full name of the plastic reel is the electronic device packaging reel, commonly referred to as a reel, a roll, and a turntable. In English, it is called a REEL. In theory, reels also come in film and box form. Generally, the film is purchased separately, while the box comes with a gift. (1) Disc type: It can be divided into 7-inch, 13-inch and 15-inch according to the diameter of the disc. The general application of the variable is 7-inch rubber disc. The fiber optic broadband is generally applied to 13-inch or 15-inch rubber disc. The material is generally selected as PS...2024-10-10 -

Anti-static embossed carrier tape

I.SMD carrier uses anti-static materials: Metals are conductors, and because the leakage current of conductors is large, it can damage devices. Additionally, because insulating materials are prone to electrostatic2024-10-10 -

Custom Embossed Carrier Tape - JiuShuo

Embossed carrier tape is mainly used in the electronic component packaging industry. It is used in conjunction with the upper sealing tape (upper sealing tape) to store components in the pockets of the carrier tape, forming a closed package by sealing the upper sealing tape over the carrier tape to prevent physical and electrostatic damage and protect the components from pollution and damage during transportation. When the electronic components are installed on the chip, the strip of the upper sealing tape is peeled off. Automatic installation devices precisely locate the components in the...2024-10-07 -

Embossed Carrier Tape And Cover Tape Factory

Anti-static is very important for carrier tape and electronic packaging. The effect of anti-static measures is directly related to the packaging effect of electronic components. For anti-static carrier tape and ic carrier tape, adding some moisture-absorbing additives is very necessary. The main purpose is to reduce the resistance of them. Such anti-static agents have very good water absorption functions and can lower the surface resistance. The main component of the anti-static agent is resin. The addition of anti-static agents to the carrier tape and the ic carrier tape during product...2024-10-07 -

Operation of a carrier tape

In the production process of carrier tape, various problems may arise, so it is necessary to adjust and handle each detail properly to ensure that the production speed of carrier tape can be controled. If the production speed is increased, the cost will go up, which is not advisable. However, if the machine is not properly adjusted, it may cause damage to the mold and have a very unfavorable impact on the carrier tape. Therefore, when problems arise in the production of carrier tape, we should promptly figure out whether they are caused by technical issues related to the production speed, ...2024-10-06

You are here:Home >> FAQ >> Company News