The company has passed the ISO9001:2015 certification and attaches great importance to product quality and environmental protection. The procurement of raw materials, product design, production, testing, sales, and after-sales service are all strictly carried out in accordance with quality standards and quality control is implemented. In the future, we will continue to strictly demand ourselves based on our industry and international standards, constantly strive for excellence in process management, strengthen consolidation, improve production and technical capabilities, and ensure stable quality. We look forward to sharing your information and cooperating with your company. Thank you!

.jpg)

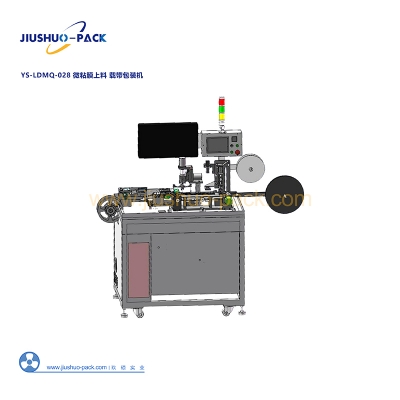

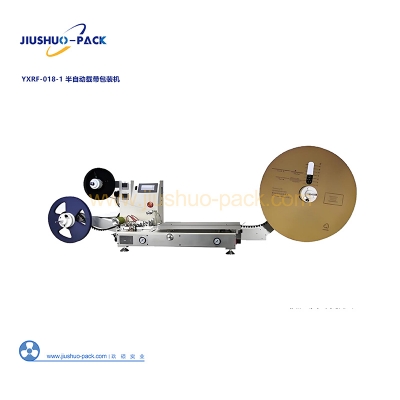

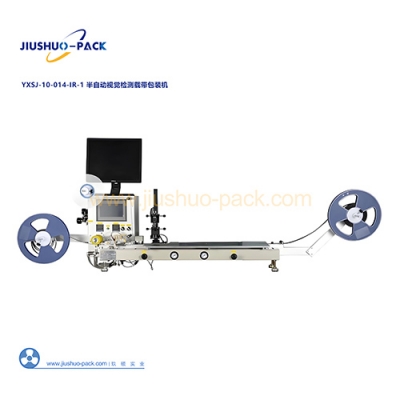

JiuShuo-Embossed carrier tape factory、The products we produce and sell include carrier tapes, reel, cover tape, and Punched paper carrier tape . Our monthly production capacity of carrier tapes can reach 38 million meters, carrier tape reel Monthly production capacity of 12 million pcs. The monthly production capacity of the upper cover belt can reach 8 million rolls. We currently have 65 carrier tape machines. 12 belt punched paper carrier tape machines. And 23 carrier tape reel injection molding machines.

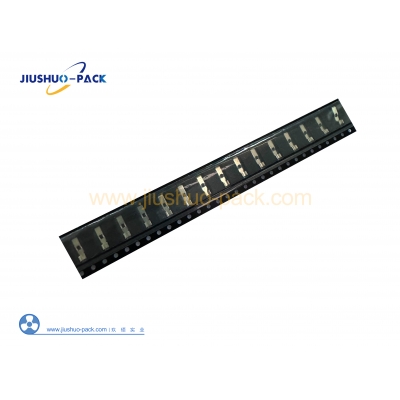

The appearance of the carrier tape is very intuitive: it is a long and thin plastic tape, with small grooves (referred to as "cavities" in the industry) dug at fixed intervals on it. All dimensions comply with the EIA-481 standard. Each groove is like a "single-person compartment" tailor-made for the part, just enough to hold a small component. After the parts are placed in the grooves, a thin cover tape will be attached to the surface of the carrier tape, tightly sealing the products in the grooves. The parts will neither fall out nor be scratched or covered with dust.

What is a carrier tape

Carrier tape is a packaging material used for carrying, transporting and protecting SMT electronic components such as chips, modules, connectors, inductors and capacitors. It is a key component for achieving efficient and automated production in modern electronics manufacturing.

In simple terms: Have you ever wondered how those electronic components smaller than fingernails in mobile phones, computers and 3C electronic products are neatly transported to the factory and pasted onto the PCB board without any damage to the products?

The answer is "carrier tape", a packaging tool that serves as a "mobile little house" for SMT tiny components.

.jpg)

.jpg)

The appearance of the carrier tape is very intuitive: it is a long and thin plastic tape, with small grooves (referred to as "cavities" in the industry) dug at fixed intervals on it. All dimensions comply with the EIA-481 standard. Each groove is like a "single-person compartment" tailor-made for the part, just enough to hold a small component. After the parts are placed in the grooves, a thin cover tape will be attached to the surface of the carrier tape, tightly sealing the products in the grooves. The parts will neither fall out nor be scratched or covered with dust.

The core identity of the carrier tape is to be a "dedicated transportation and storage container for tiny parts", ranging from connectors and modules a few millimeters in size, precision hardware components, to chips smaller than sesame seeds, all of which are the objects of carrier tape packaging.

When the SMT assembly factory is in production, workers only need to install the carrier tape on the automated equipment, and the machine can precisely lift the cover tape and remove the components. There is no need to manually mount them one by one on the PCB, or cause pollution and damage. Efficient automated production is achieved through carrier tape packaging.